Extending the Power of Stabilized PLOT Column Technology to Process GC Analyzers

Restek Corporation, 110 Benner Circle, Bellefonte, PA, US

* Restek Corporation, Weerhaan 9, Middelburg, The Netherlands

Recent advances in PLOT column technology that were first developed in fused silica have now been transferred to metal MXT PLOT columns. These new columns offer greater stability than conventional PLOT columns, making them a more reliable choice for continual process monitoring. Advantages include highly reproducible flow characteristics, improved layer stability, and excellent separation efficiencies.

Porous layer open tubular (PLOT) columns are useful for analyzing volatiles in petrochemical product streams, as the specialized adsorbents provide good resolution and fast analysis times. However, conventional PLOT columns suffer from poor mechanical stability, limiting their use in process analyzers which require robust columns for continual operation. Recently Restek developed new PLOT column bonding techniques that resulted in improved layer stability, consistent flow behavior, and more reproducible retention times. This technology, which was first developed for fused silica columns, is now being used with metal MXT tubing, resulting in rugged columns that outperform typical metal PLOT columns. Exceptionally stable, new MXT PLOT columns provide efficient resolution and reliable performance, making them ideal for process GC analyzers.

New Technology Increases Reliability and Reproducibility

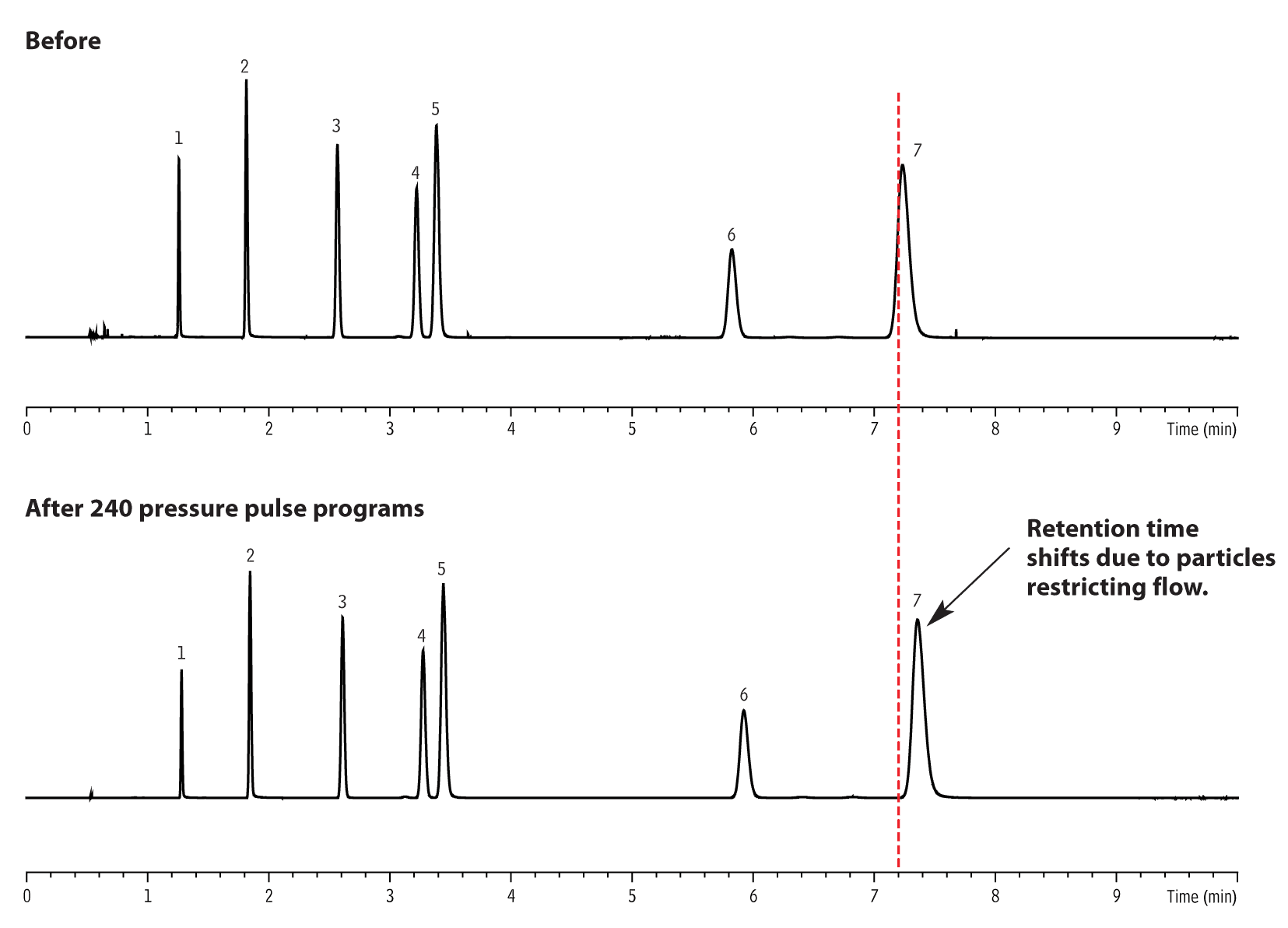

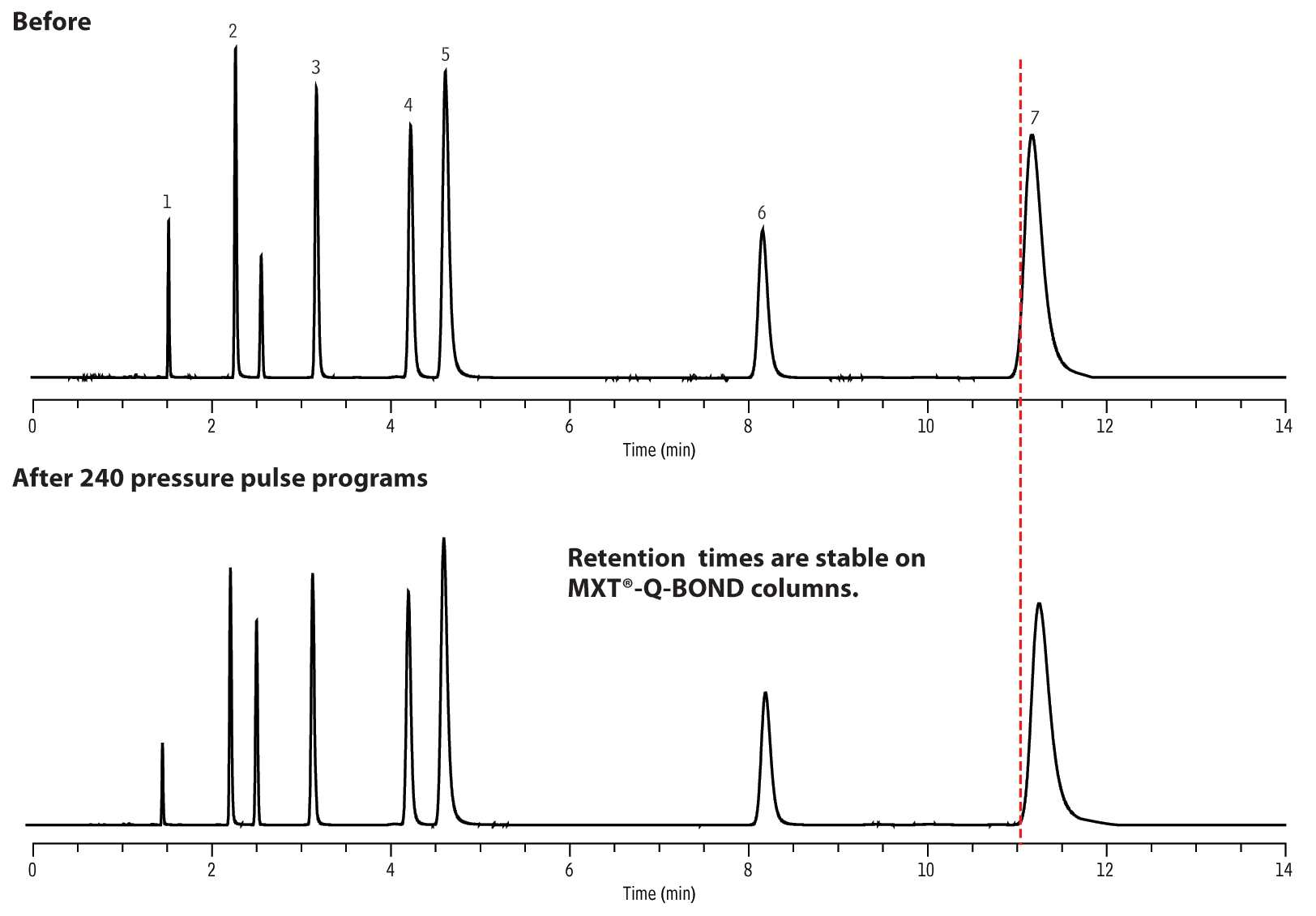

Restek’s PLOT columns are stabilized through a proprietary process that is based on concentric adsorption layers and improved particle bonding. The resulting columns are more stable than conventional PLOT columns and have much more reproducible flow behavior. To demonstrate the superior stability of MXT PLOT columns, an MXT-Q-BOND column and a competitor’s Q type column were subjected to 240 pressure pulse cycles and the spiking observed in each analytical run was used as an indicator of particle generation or phase instability. Results demonstrate that particle generation on the vendor V column was significantly higher (Figure 1), resulting in restrictions in the column that caused a shift in retention time (Figure 2). In contrast, the MXT-Q-BOND column showed little spiking. Greater phase stability resulted in consistent flow behavior and predictable retention times (Figure 3).

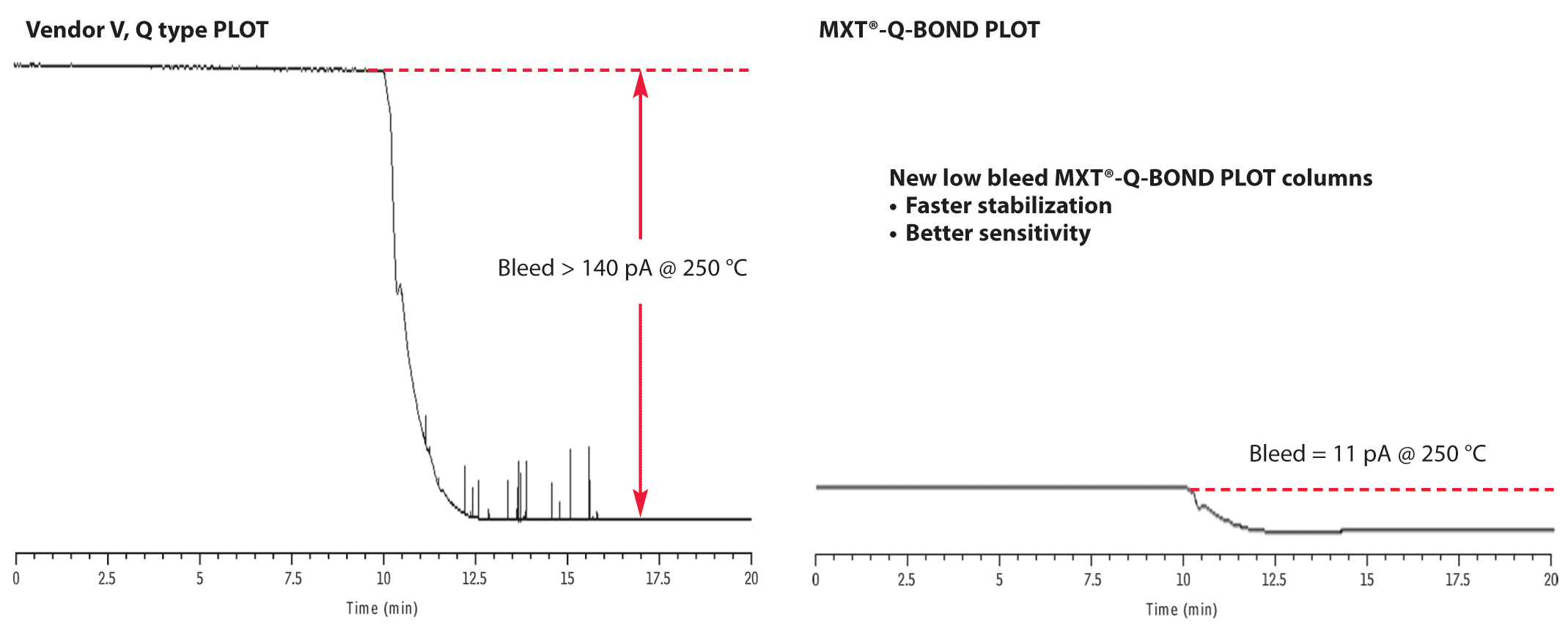

In addition to more consistent flows and reliable retention times, new MXT PLOT columns show greater thermal stability and much less phase bleed than the comparable competitor product (Figure 4). Lower bleed improves sensitivity and ensures faster stabilization times. In addition, because less stationary phase is lost, retention times are more stable over the lifetime of the column.

Key Phases Available for Optimized Separations

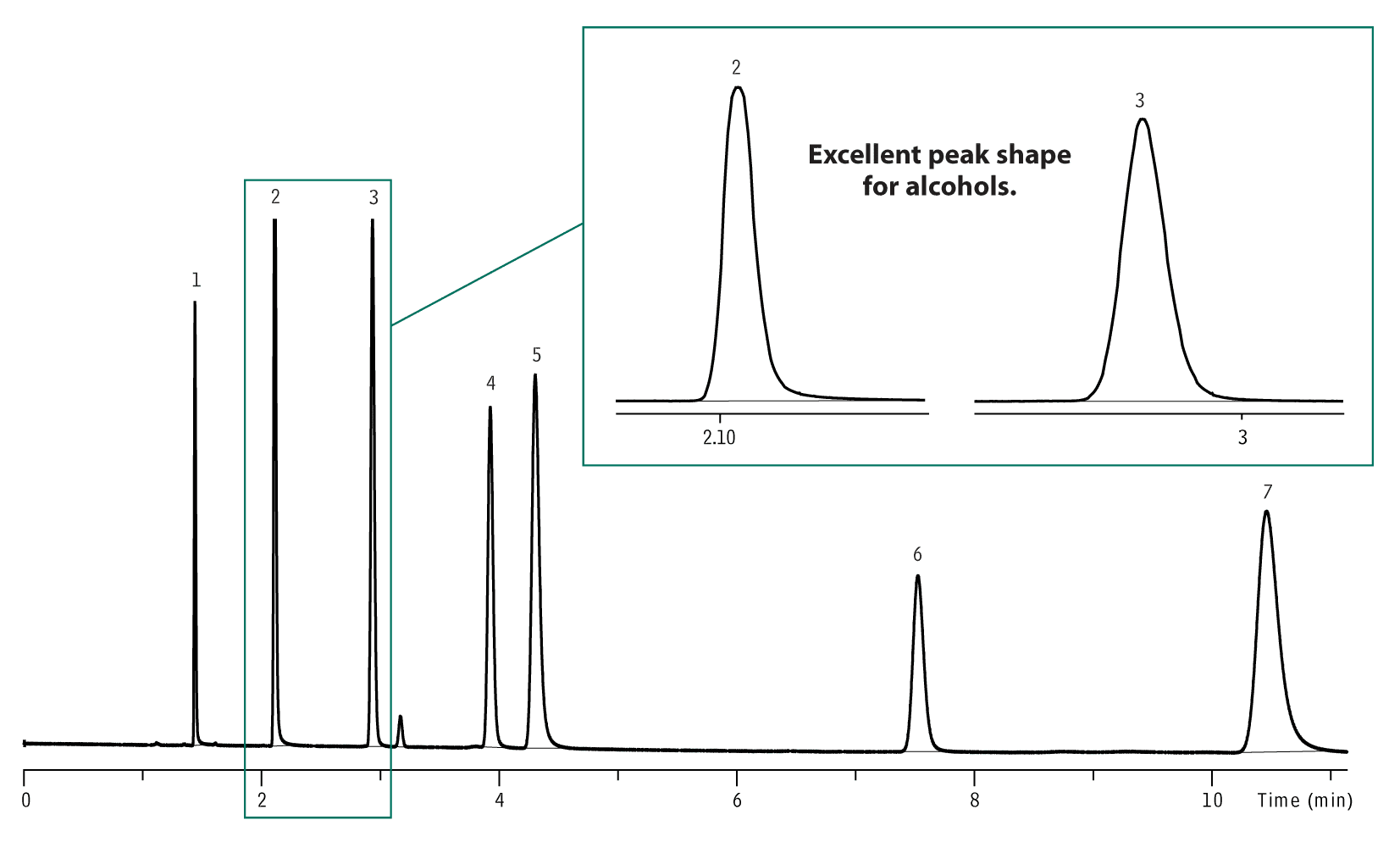

Metal MXT columns are available for all major adsorbent types: porous polymer, molecular sieve, and alumina. Porous polymer MXT columns are highly inert and effective at separating both polar and nonpolar compounds. Volatiles are strongly retained, making these columns extremely useful for separating many target analytes. As shown in Figure 5, MXT-Q-BOND columns provide excellent chromatography for challenging solvents—even alcohols elute as sharp, symmetric peaks.

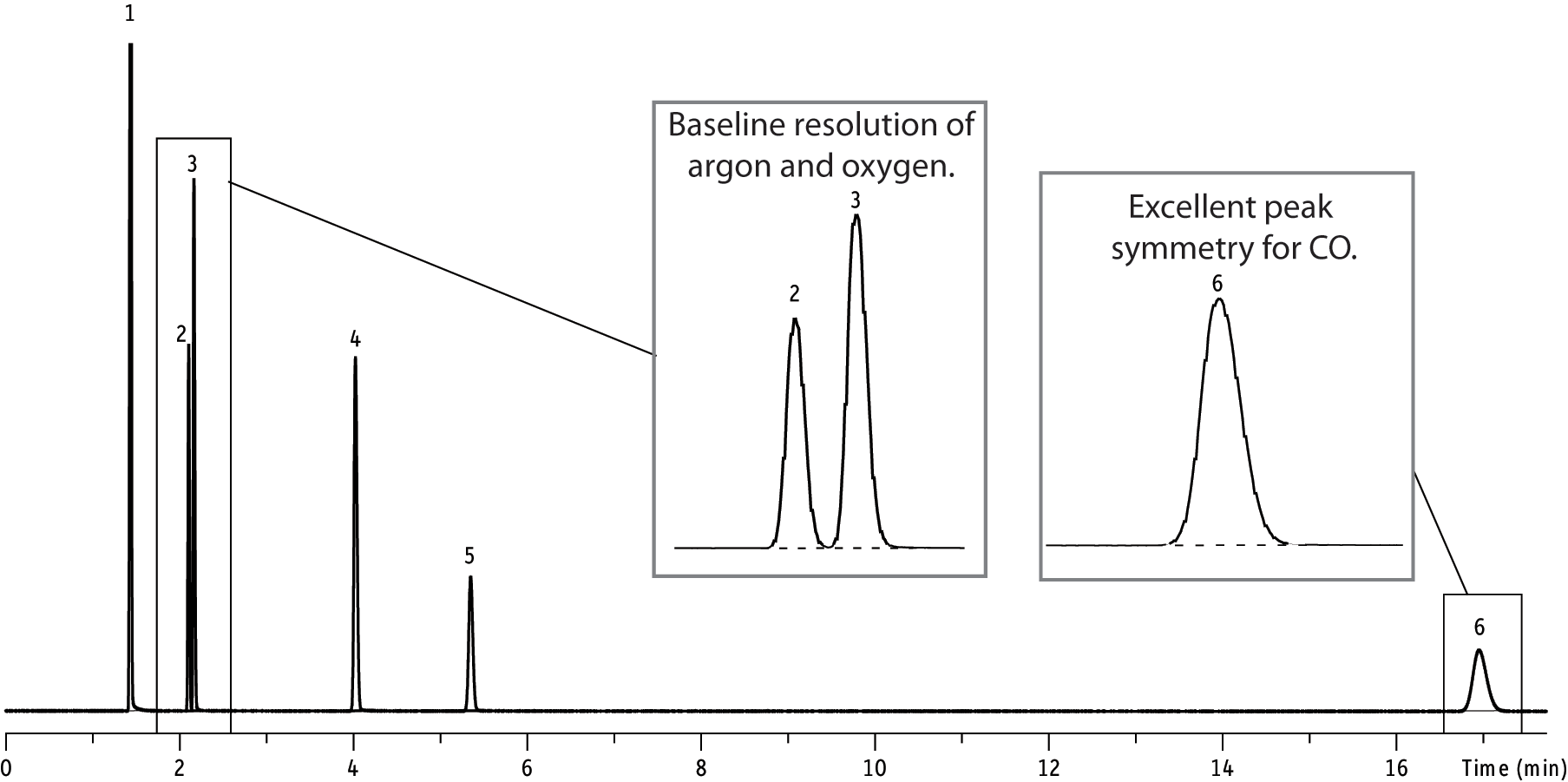

MXT-Msieve 5A columns provide efficient separation of argon and oxygen, as well as other permanent gases (Figure 6). Special coating and deactivation procedures ensure chromatographic efficiency and the integrity of the porous layer coating. The unique immobilization process guarantees that particles remain adhered to the tubing, which is particularly valuable for flow and valve switching applications and allows these procedures to be run with greater confidence.

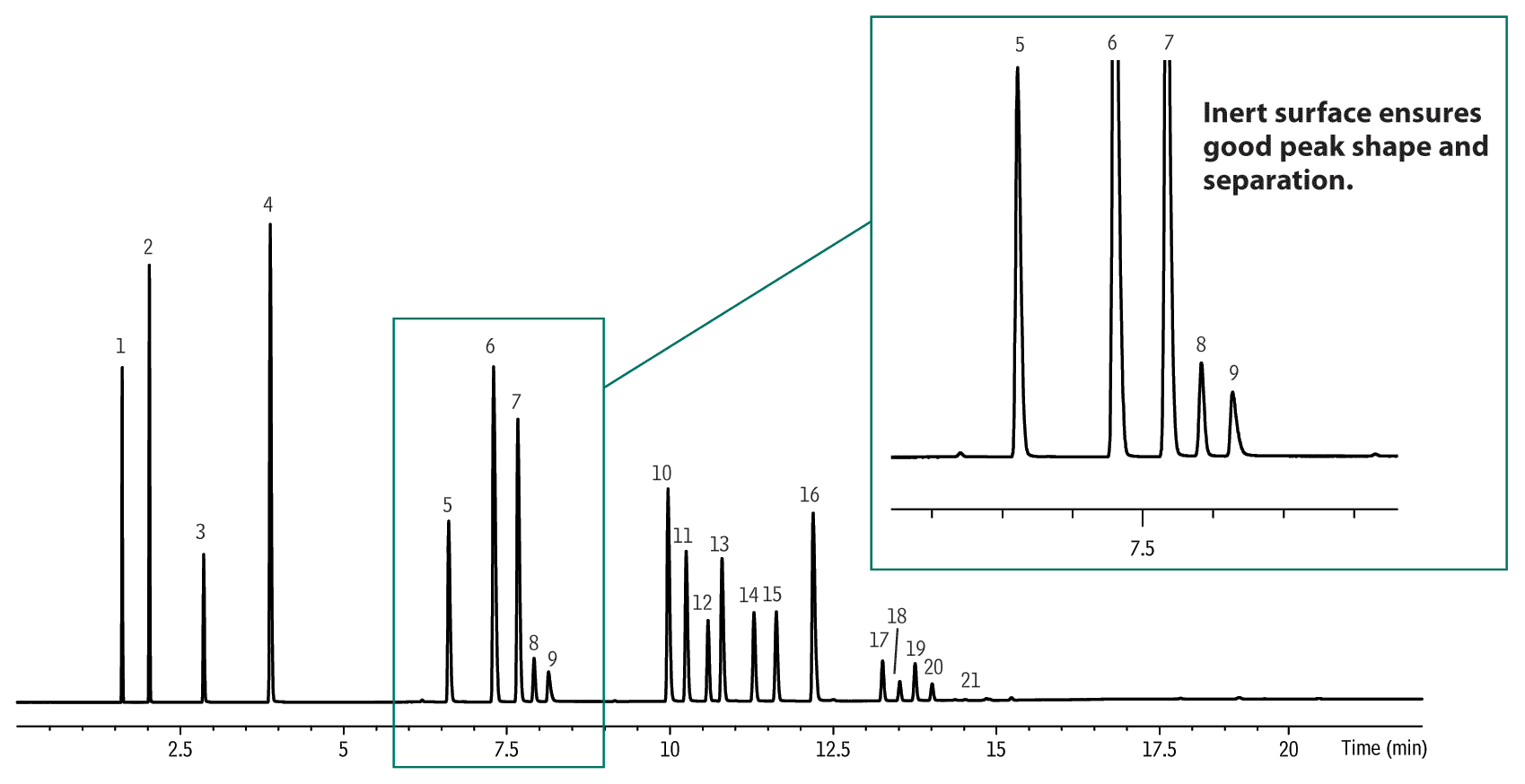

Metal alumina columns are recommended for light hydrocarbon analysis, as alumina is one of the most selective adsorbents available and allows all C1-C5 isomers to be separated with the highest degree of resolution. As shown in Figure 7, MXT-Alumina PLOT columns provide excellent chromatographic separation of refinery gas components. Peaks are fully resolved and symmetric, showing no sign of degradation or reactivity with the metal tubing.

Summary

New MXT PLOT columns from Restek offer greater stability than conventional PLOT columns, making them a better choice for process monitoring. New bonding techniques produce columns with highly reproducible flow characteristics, improved layer stability, and excellent separation efficiencies. These robust columns produce exceptionally reproducible chromatography, providing the reliable performance needed for process GC analyzer applications.

Figure 1: New bonding technology in MXT PLOT columns results in greater phase stability and reduced particle generation, compared to conventional PLOT columns.

Figure 2: Vendor V PLOT columns release particles following pressure pulsing, forming restrictions in the column that affect flow behavior and change retention time.

| Peaks | |

|---|---|

| 1. | Methane |

| 2. | Methanol |

| 3. | Ethanol |

| 4. | Acetone |

| 5. | Diethylether |

| 6. | Ethyl acetate |

| 7. | Hexane |

| Column | Vendor V, Q PLOT, 25 m, 0.53 mm ID |

|---|---|

| Standard/Sample | Solvent mix |

| Injection | |

| Inj. Vol.: | 1.0 µL split |

| Inj. Temp.: | 250 °C |

| Split Vent Flow Rate: | 150 mL/min. |

| Oven | |

| Oven Temp.: | 150 °C |

| Carrier Gas | H2, constant pressure (4 psi, 27.6 kPa) |

| Detector | FID @ 250 °C |

|---|---|

| Instrument | Agilent/HP6890 GC |

| Notes | Pressure pulse test = 240 cycles |

Figure 3: MXT PLOT columns are exceptionally stable; flow characteristics and retention times are highly consistent and not affected by pressure pulses.

| Peaks | |

|---|---|

| 1. | Methane |

| 2. | Methanol |

| 3. | Ethanol |

| 4. | Acetone |

| 5. | Diethylether |

| 6. | Ethyl acetate |

| 7. | Hexane |

| Column | MXT-Q-BOND, 30 m, 0.53 mm ID, 20 µm (cat.# 79716) |

|---|---|

| Standard/Sample | Solvent mix |

| Injection | |

| Inj. Vol.: | 1.0 µL split |

| Inj. Temp.: | 250 °C |

| Split Vent Flow Rate: | 150 mL/min. |

| Oven | |

| Oven Temp.: | 150 °C |

| Carrier Gas | H2, constant pressure (4 psi, 27.6 kPa) |

| Detector | FID @ 250 °C |

|---|---|

| Instrument | Agilent/HP6890 GC |

| Notes | Pressure pulse test = 240 cycles |

Figure 4: The bonding technology used in new MXT PLOT columns increases thermal tolerance, resulting in lower bleed, faster stabilization times, and higher sensitivity.

| Column | See notes for column descriptions. |

|---|---|

| Standard/Sample | |

| Injection | split |

| Inj. Temp.: | 250 °C |

| Split Vent Flow Rate: | 150 mL/min. |

| Oven | |

| Oven Temp.: | 250 °C (hold 10 min) to 40 °C at 50 °C/min |

| Carrier Gas | H2, constant pressure (4 psi, 27.6 kPa) |

| Detector | FID @ 250 °C |

|---|---|

| Instrument | Agilent/HP6890 GC |

| Notes | Columns tested: Vendor V, metal Q type column Restek MXT-Q-BOND Columns were conditioned at 250 °C for the same length of time, and then bleed was compared to demonstrate the temperature stability of each column. Lower bleed columns allow higher sensitivities and faster stabilization times. |

Figure 5: Sharp, symmetric solvent peaks are obtained on an MXT-Q-BOND PLOT column.

| Peaks | |

|---|---|

| 1. | Methane |

| 2. | Methanol |

| 3. | Ethanol |

| 4. | Acetone |

| 5. | Diethylether |

| 6. | Ethyl acetate |

| 7. | Hexane |

| Column | MXT-Q-BOND, 30 m, 0.53 mm ID, 20 µm (cat.# 79716) |

|---|---|

| Standard/Sample | Solvent mix |

| Injection | split |

| Inj. Temp.: | 250 °C |

| Split Vent Flow Rate: | 200 mL/min. |

| Oven | |

| Oven Temp.: | 150 °C |

| Carrier Gas | H2, constant flow |

| Linear Velocity: | 40 cm/sec |

| Detector | FID |

|---|---|

| Instrument | Agilent/HP6890 GC |

Figure 6: Permanent gases, including argon and oxygen, are fully separated on an MXT-Msieve 5A column using a µ-TCD.

| Column | MXT-Msieve 5A, 30 m, 0.53 mm ID, 50 µm (cat.# 79723) |

|---|---|

| Standard/Sample | |

| Conc.: | 1% in hydrogen |

| Injection | split (split ratio 50:1) |

| Oven | |

| Oven Temp.: | 30 °C |

| Carrier Gas | H2 |

| Detector | μ-TCD |

|---|

Figure 7: Highly inert MXT-Alumina BOND columns provide reliable baseline separation of refinery gas components.

| Peaks | |

|---|---|

| 1. | Methane |

| 2. | Ethane |

| 3. | Ethylene |

| 4. | Propane |

| 5. | Propylene |

| 6. | Isobutane |

| 7. | n-Butane |

| 8. | Propadiene |

| 9. | Acetylene |

| 10. | trans-2-Butene |

| Peaks | |

|---|---|

| 11. | 1-Butene |

| 12. | Isobutylene |

| 13. | cis-2-Butene |

| 14. | Isopentane |

| 15. | n-Pentane |

| 16. | 1,3-Butadiene |

| 17. | trans-2-Pentene |

| 18. | 2-Methyl-2-butene |

| 19. | 1-Pentene |

| 20. | cis-2-Pentene |

| 21. | Hexanes |

| Column | MXT-Alumina BOND/Na2SO4, 30 m, 0.53 mm ID, 10 µm (cat.# 79714) |

|---|---|

| Standard/Sample | Refinery gas |

| Injection | |

| Inj. Vol.: | 10 µL split |

| Liner: | 2 mm split |

| Inj. Temp.: | 45 °C |

| Split Vent Flow Rate: | 80 mL/min. |

| Oven | |

| Oven Temp.: | 45 °C (hold 1 min) to 200 °C at 10 °C/min (hold 8.5 min) |

| Carrier Gas | He, constant pressure (10 psi, 68.9 kPa) |

| Linear Velocity: | 31 cm/sec @ 45 °C |

| Detector | FID @ 200 °C |

|---|