Get Equivalent GC-MS Results Faster with Restek’s GC Accelerator Kit and EZGC Method Translator

Would you like to significantly reduce your current GC-MS analysis time while maintaining the same chromatographic separation? The combination of using a GC Accelerator oven insert kit and adapting an existing method to a scaled-down, more efficient column using our EZGC method translator is a surprisingly simple means of speeding up your analyses to get similar results faster.

The GC Accelerator kit for Agilent GCs helps increase speed because the insulated inserts fill the oven cavity, creating a smaller volume to heat and cool (Figure 1). This allows you to significantly increase ramp rates on your existing instrument, which provides an easy means of speeding up analysis time without any changes to hardware or software. Also, GC Accelerator inserts were designed with GC-MS users in mind, so they fit easily into the oven without interfering with an inlet installed in the front position or with the MS transfer line interface.

Figure 1: GC Accelerator oven inserts speed up analysis times by reducing oven volume, which allows for faster ramp rates.

Faster analyses can also be obtained on any GC by moving to a shorter column with a narrower inner diameter (ID) and thinner film. A smaller ID and thinner film results in a more efficient column that produces narrower peaks, which allow relative peak separations to be maintained and compressed into shorter run times. Note that when changing column dimensions, it’s important to adjust the inner diameter and film thickness proportionally so the phase ratio stays the same. The more efficient column will also be shorter than the original. The more efficient column will have more plates per meter, but to properly scale down you need to maintain the same number of total plates, which is why the new column will be shorter. However, just properly scaling down the column won’t give you the same results in less time. To get the same results faster, you need to adjust key method parameters to account for the shorter, more efficient column. Fortunately, that’s easy to do using EZGC method translation software. Let’s walk through an example to show you how.

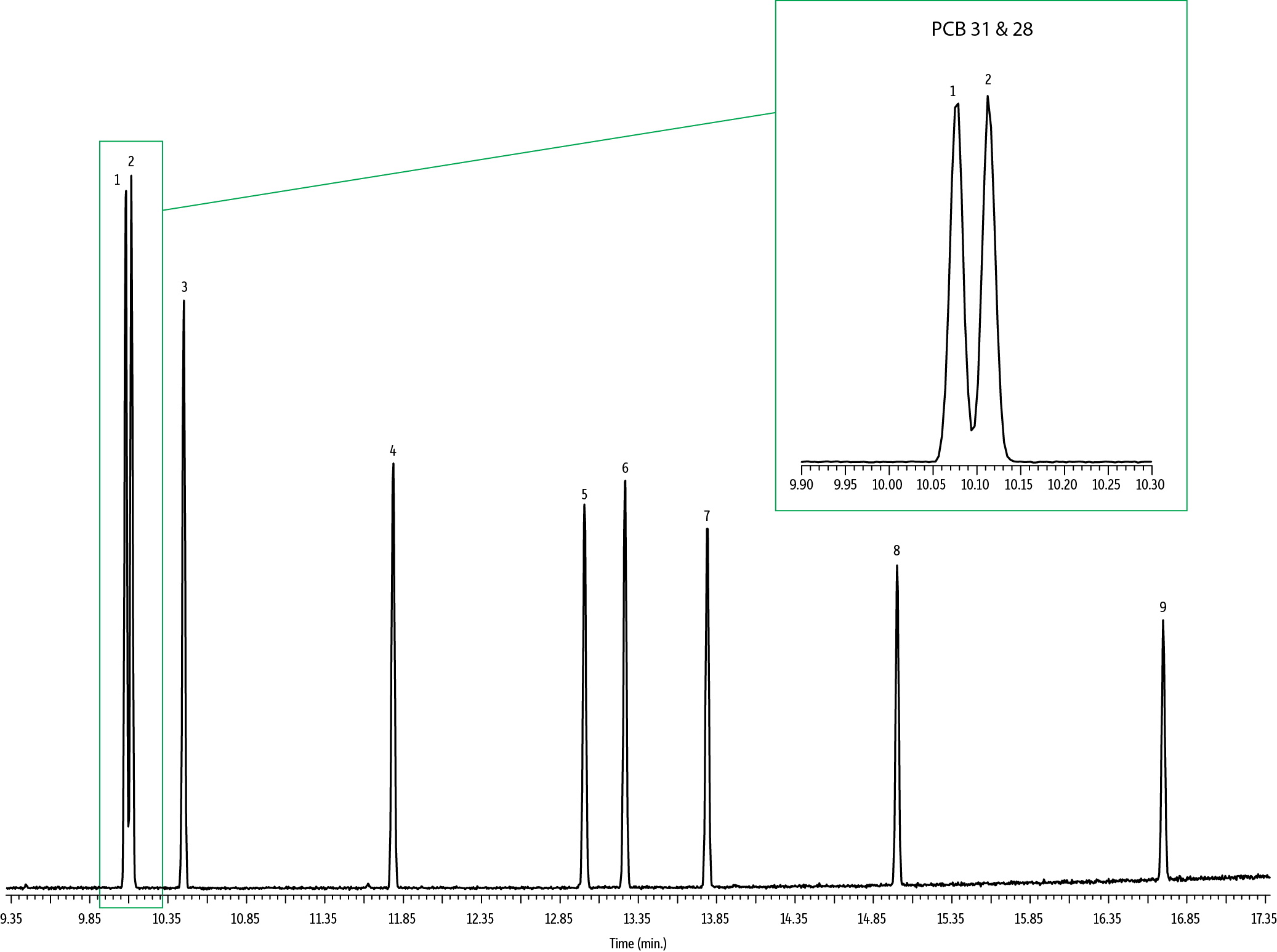

For our demonstration, let’s say you’re performing PCB analyses on an Agilent GC-MS using the conditions shown in Figure 2. You’re happy with the separation, but want to shorten analysis time so you can analyze more samples per shift. The first step is to select a scaled-down column with the same phase ratio and total number of theoretical plates.

Figure 2: Current Column Dimensions and Method Conditions

| Column | Rxi-XLB, 30 m, 0.25 mm ID, 0.25 µm (cat.# 13723) |

|---|---|

| Standard/Sample | PCB congener standard #2 (cat.# 32294) |

| PCB 31 (custom) | |

| Diluent: | Dichloromethane |

| Conc.: | 3.5 ppm |

| Injection | |

| Inj. Vol.: | 0.5 µL splitless (hold 1.75 min) |

| Liner: | 2.0 mm ID straight inlet liner w/wool (cat.# 21718) |

| Inj. Temp.: | 300 °C |

| Purge Flow: | 50 mL/min |

| Oven | |

| Oven Temp.: | 40 °C (hold 2 min) to 240 °C at 30 °C/min (hold 2 min) to 340 °C at 10 °C/min (hold 5 min) |

| Carrier Gas | He, constant flow |

| Flow Rate: | 1 mL/min |

| Detector | MS |

|---|---|

| Mode: | Scan |

| Transfer Line Temp.: | 300 °C |

| Analyzer Type: | Quadrupole |

| Source Temp.: | 280 °C |

| Electron Energy: | 70 eV |

| Ionization Mode: | EI |

| Scan Range: | 45-550 amu |

| Scan Rate: | 5 scans/sec |

In this example, we are switching from a 30 m, 0.25 mm, 0.25 µm column to a 20 m, 0.15 mm, 0.15 µm column. To obtain the translated method conditions that provide the same chromatographic separation in less time on the new column, follow the steps below. Go to www.restek.com/ezgc-mtfc if you’d like to try using the EZGC method translator (Figure 3) yourself as we move through the example.

Figure 3: EZGC Method Translator (Default Settings)

Step 1: Select the correct carrier gas for your method.

Step 2: Enter your current column dimensions.

Step 3: Enter your current method’s column flow. Note that average velocity, holdup time, and inlet pressure will autofill based on the column flow you specify. Because this is a MS method, make sure the outlet pressure (abs) value is set to 0 psi and the vacuum button is selected. These are the default selections, but note that the modeler output would be different if you were using an FID, for instance, and the outlet pressure (abs) was atmospheric pressure instead of the vacuum generated by a mass spectrometer.

Step 4: Enter your current oven program.

Step 5: Make sure the control method is correct and the default radio button “Translate” is selected. By choosing the “Translate” option, you are asking the EZGC method translator to balance speed and efficiency.

Step 6: Enter the new column dimensions and the EZGC method translator will do the rest of the work and provide the following properly translated method parameters that will give an equivalent separation in less time on the scaled-down column you selected.

a) New column flow and the subsequently calculated flow-related parameters.

b) New oven ramp rates.

c) New shorter analysis time for the same separation.

In this example, we’re seeing a savings of almost 8 minutes, almost 30%, in analysis time. Put simply, this change would allow an instrument to complete a sequence of samples that normally would take 8 hours in a little more than 5.5 hours. We also see an example of the value of using the GC Accelerator oven insert. Figure 4 displays the new oven program, which has a starting ramp of 42.7 °C/min up to 240 ˚C. A standard 100/120 V oven just won’t ramp that fast. In fact, even the faster-ramping 200/220/230/240 V oven only barely meets this requirement, and then only if everything is in pristine condition. Retention times can vary significantly if the oven isn’t able to achieve the programed ramp rate, causing problems with peak identification and quantitation. However, aggressive ramp rates like this one can reliably be achieved with the GC Accelerator inserts installed. Table I compares the maximum rates that can be obtained with and without the inserts installed in Agilent ovens.

Figure 4: The GC Accelerator insert kit reduces oven volume, which shortens heating/cooling times and allows aggressive ramp rates to be met.

Table I: Maximum Ramp Rates in an Agilent GC-MS Oven with and without GC Accelerator Inserts Installed.

| Temperature Range (˚C) | 120 V Oven Ramp Rate (˚C/min) | >200 V Oven Ramp Rate (˚C/min) | ||

| Without GC Accelerator | With GC Accelerator | Without GC Accelerator | With GC Accelerator | |

| 50–70 | 75 | 120 | 120 | 120 |

| 70-115 | 45 | 95 | 95 | 120 |

| 115-175 | 40 | 65 | 65 | 110 |

| 175-300 | 30 | 40 | 45 | 70 |

| 300-350* | 20 | 30 | 35 | 65 |

* Agilent ovens are programmable to 450 ˚C, but this product was only tested to 350 ˚C. Prior to analysis, confirm the analytical column can withstand the temperatures and ramp rates you plan to use.

With the GC Accelerator kit installed, you can obtain the same separation while speeding up your analysis. To show you the results, we entered the translated method parameters into the Pro EZGC chromatogram modeler (available at www.restek.com/proezgc). As demonstrated by the simulated chromatogram in Figure 5, comparable chromatography can be achieved in a much faster analysis time using the new column dimensions and instrument conditions. In fact, with the final peak eluting at 11.5 minutes under the new set of conditions, thought could be given to changing the end of the method to ramp quicker or end sooner, resulting in an even shorter analysis than the direct translation calculates.

Figure 5: Comparison of original method and modeled results based on the shorter column and translated method. The translated method provides the same elution order and relative peak separation, but the peaks elute in a much shorter analysis time.

Original Method (30 m, 0.25 mm, 0.25 µm column)

Translated Method (20 m, 0.15 mm, 0.15 µm column)

The last thing you’ll need to keep in mind if you implement these changes is that the move to a narrower, thinner film column will best be paired with the adoption of a split injection mode. It’s possible that you’re currently using a splitless injection to enhance the sensitivity of your analysis, but the much higher efficiency this change will provide produces narrower, taller peaks, which itself is a boost in sensitivity. That boost should allow you to still meet your detection limits even when using a split injection.

The value of the split injection is two-fold. First, if there were any loading capacity concerns with a thinner film producing overloaded, fronting peaks, the split injection will take care of that. Second, the biggest benefit is the very rapid transfer of the sample onto the column, which will help keep the bands of molecules narrow, and, as a result, your peaks narrow. The relatively slow transfer time of a splitless injection, especially one into a relatively wide inlet liner (e.g., a 4 mm ID single taper with wool), will cause band broadening, and consequently, peak widening, and that might negate some of the efficiency benefits of the new column dimension. Moving to a split injection will also mean you can keep using your typical liner instead of trying to switch to a narrower one to maintain overall efficiency.

In conclusion, equivalent chromatographic results can be obtained in much faster analysis times for many applications by moving to a scaled-down, more efficient column with the same phase ratio. EZGC method translation software from Restek makes it exceptionally easy to do this on any GC system, and the translated method can be even further optimized if desired. When moving to a translated method, make sure that the new oven program does not exceed the capabilities of your oven. Agilent GC-MS users can use GC Accelerator oven inserts to achieve more aggressive oven programs. These inserts reduce oven volume, which allows the oven to heat and cool faster, ultimately resulting in faster analyses.