- High-polarity, stable polyethylene glycol (PEG) stationary phase.

- Low bleed and rugged enough to withstand repeated temperature cycles without retention time shifting.

- Ideal for food, flavor, fragrance, and industrial

chemical and solvent analysis.

Stabilwax-MS Columns

| Stabilwax-MS Features |

Your Benefit |

| High thermal stability polyethylene glycol (PEG) stationary phase |

Able to couple to MS detector Temperature range: 40 °C to 260 °C |

| Lower bleed than VF-WAXms |

Lower detection limits |

| Ultra-clean, Restek-manufactured phase and bonding chemistries |

Extraordinary inertness and stability against chemicals and high temperatures |

| Withstand repeated water injections with no phase loss or degradation |

Longer column lifetime and solvent rinseable |

| Equivalent to USP G14, G15, G16, G20, and G39 phases |

Ideal for polar analytes in foods, flavors, fragrances, industrial chemicals, and solvents |

Challenges of Polar Compound Analysis by GC

One of the most widely used columns in gas chromatography is a polyethylene glycol (PEG) or “wax” phase. This unique column is highly polar compared to nonpolar methyl phases like Rxi-1 columns (100% dimethyl polysiloxane) or Rxi-5 columns (5% diphenyl/95% dimethyl polysiloxane) due to the presence of a polyethylene glycol backbone (Figure 1). The incorporation of the oxygen group in the backbone creates a phase with high selectivity for polar analytes, such as alcohols, glycols, esters, and ethers. These compound classes are commonly found in pharmaceutical raw materials, alcoholic beverages, industrial chemicals, flavors, and fragrances. A wax phase is capable of providing resolution of these compound classes that will not be achievable on nonpolar and intermediate polarity columns.

Due to phase structure, wax columns typically have lower maximum operating temperatures (240-250 °C) than nonpolar columns (e.g., max temp of an Rxi-5ms column is 360 °C) and exhibit higher column bleed levels than silicone phases. Because of this, retention time shifting can occur on some wax columns due to the loss of stationary phase (column bleed) that occurs during GC oven temperature cycling. Wax phases are also susceptible to oxygen contamination and can degrade quickly if exposed to oxygen from a leak in the GC at high temperatures. Oxygen contamination is chromatographically seen as a high column baseline that cannot be decreased by column conditioning or maintenance. A Restek electronic leak detector is the best way to ensure a leak-free system and long column lifetimes. See page 12 for details on this product and view the leak-checking demo on our website for how to properly use an electronic leak detector.

Figure 1: The highly polar nature of the Stabilwax-MS column makes it ideal for separating polar compounds found in food, flavors, fragrances, pharmaceutical raw materials, and industrial chemicals.

Over the past several years, benchtop mass spectrometer (MS) detectors have become the GC detector of choice since they provide high sensitivity, quantitative retention time data, and compound identification. GC-MS users have long wanted thermally stable polar phases to use with their MS systems to take advantage of their unique selectivity without the worry of the column bleed seen on most wax columns.

Stabilwax-MS Columns: A Wax Phase Suitable for GC-MS

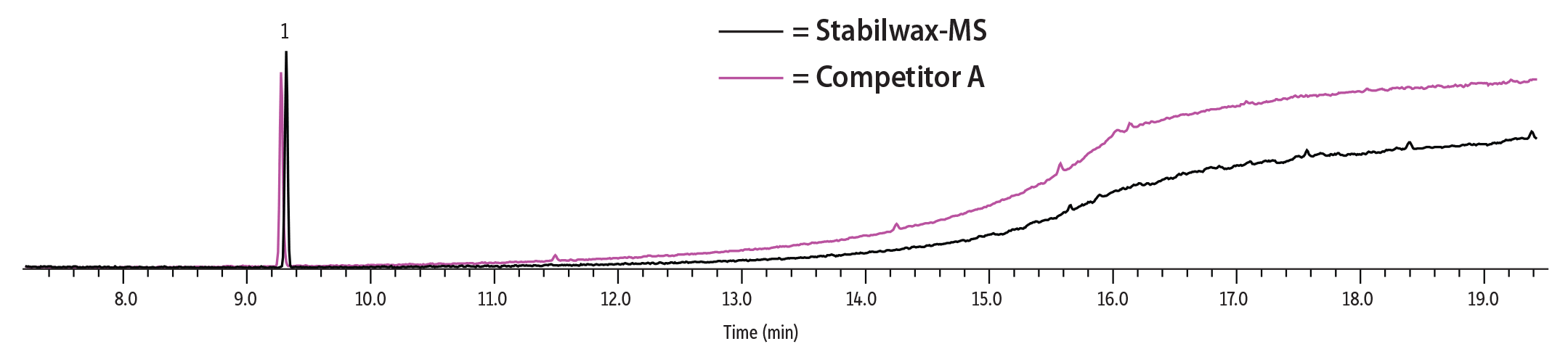

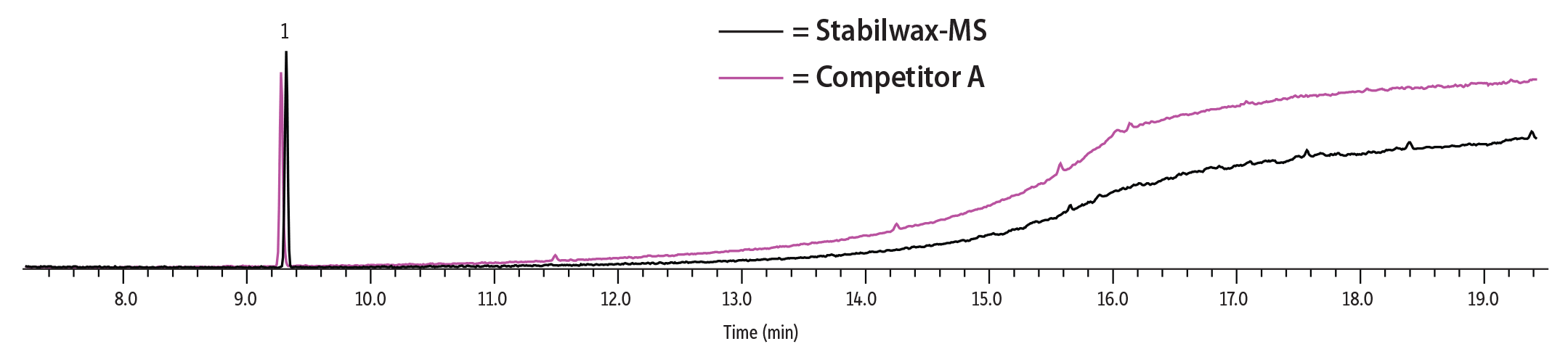

The Stabilwax-MS column from Restek meets a GC-MS user’s challenges. The polar deactivated surface tightly binds the polyethylene glycol polymer to the fused silica tubing, resulting in a high maximum operating temperature (260 °C). This allows for faster elution of higher molecular weight compounds since the column can be taken to high temperatures. In addition, low-bleed levels are ensured by strict quality testing that specifies maximum allowable bleed levels of 4.0 pA for 0.25 mm ID columns and 5.0 pA for 0.32 mm ID columns. When comparing actual bleed levels on a mass spectrometer, Stabilwax-MS columns outperform the VF-WAXms column (Figure 2). When tested at the 250 °C temperature limit of the VF-WAXms column, less bleed is seen on the Stabilwax-MS column.

The low-bleed level of the Stabilwax-MS column makes it suitable for GC-MS analysis of a wide range of polar compounds and matrices, including FAMEs, flavor compounds; essential oils; solvents; aromatics (including xylene isomers); acrolein/acrylonitrile; and oxygenated compounds. The Stabilwax-MS column is also useful for purity testing of chemicals and analyzing impurities in water and alcoholic beverages. When methods require trace analysis, the highly polar, low-bleed Stabilwax-MS column produces excellent results compared to conventional wax columns. Review the applications in this brochure and try a low-bleed Stabilwax-MS column for yourself!

Figure 2: Stabilwax-MS columns exhibit lower bleed levels than VF-WAXms columns and are stable up to 260 °C.

GC_GN1165

GC_GN1165

* Reference peak for MS response comparison

| Stabilwax-MS, 30 m, 0.25 mm ID, 0.25 µm (cat.# 10673) |

| Acetonitrile |

| 2 µg/mL |

| 1 µL splitless (hold 0.50 min) |

| Premium 3.5 mm single taper w/wool (cat.# 23322) |

| 250 °C |

| 5 mL/min |

| 40 °C (hold 2 min) to 250 °C at 15 °C/min (hold 5 min) |

| 1.0 mL/min |

| 36.1 cm/sec @ 40 °C |

| MS |

| Scan |

|

| Group | Start Time

(min) | Scan Range

(amu) | Scan Rate

(scans/sec) |

|---|

| 1 | 0.50 | 45-550 | 2 |

|

| 260 °C |

| Quadrupole |

| 250 °C |

| 70 eV |

| 0.50 min |

| PFTBA |

| EI |

Fragrance Analysis

Commercial Perfumes

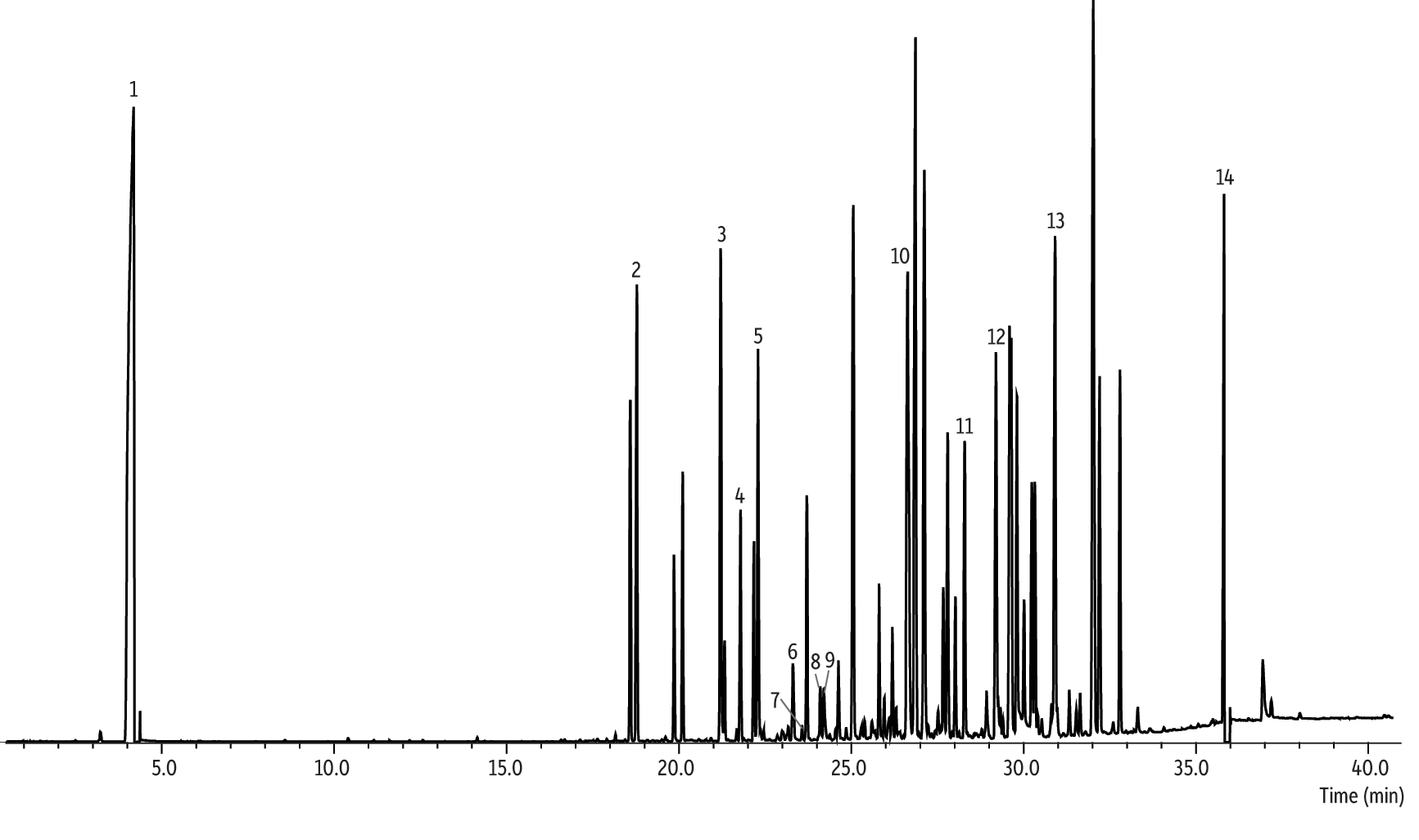

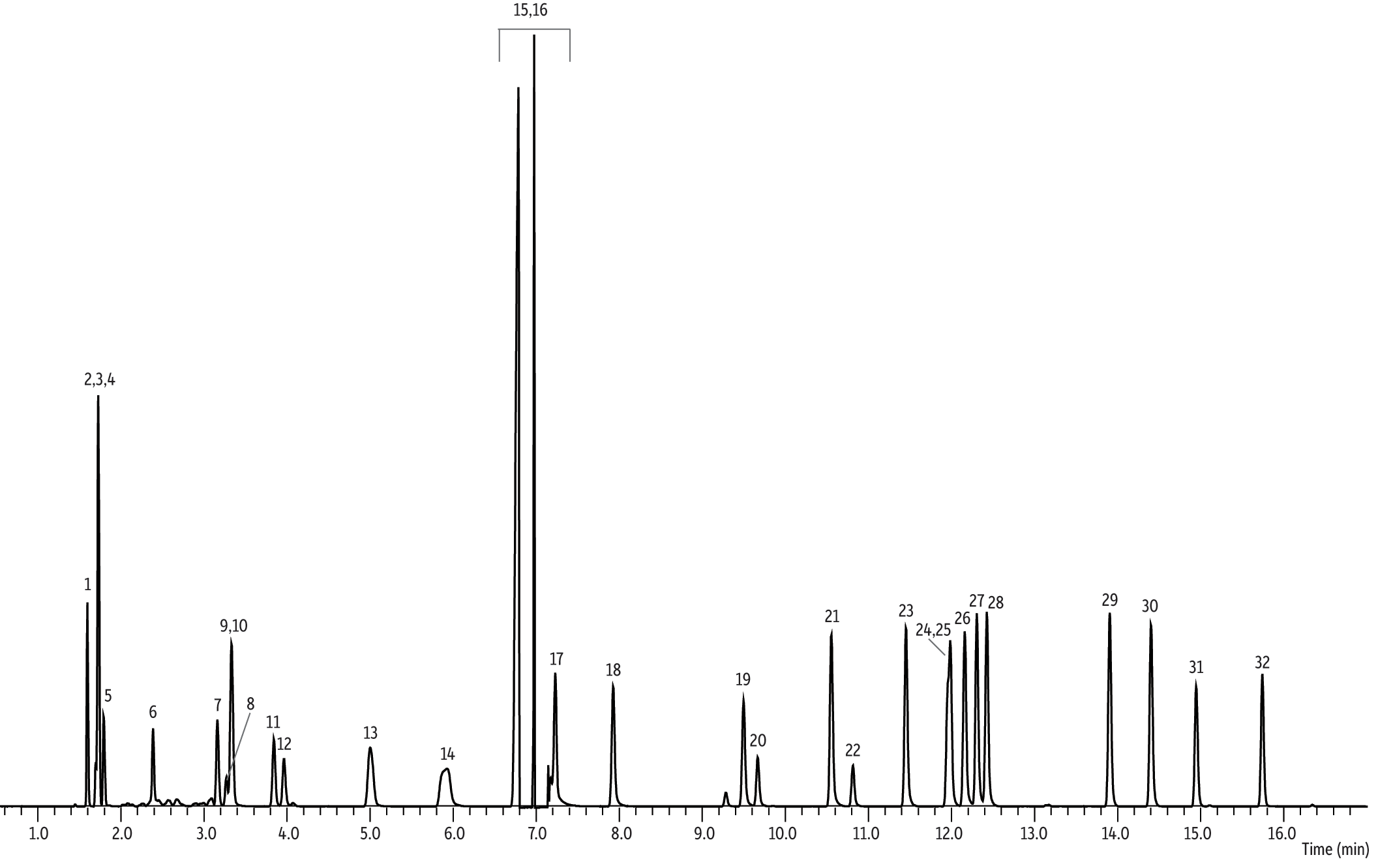

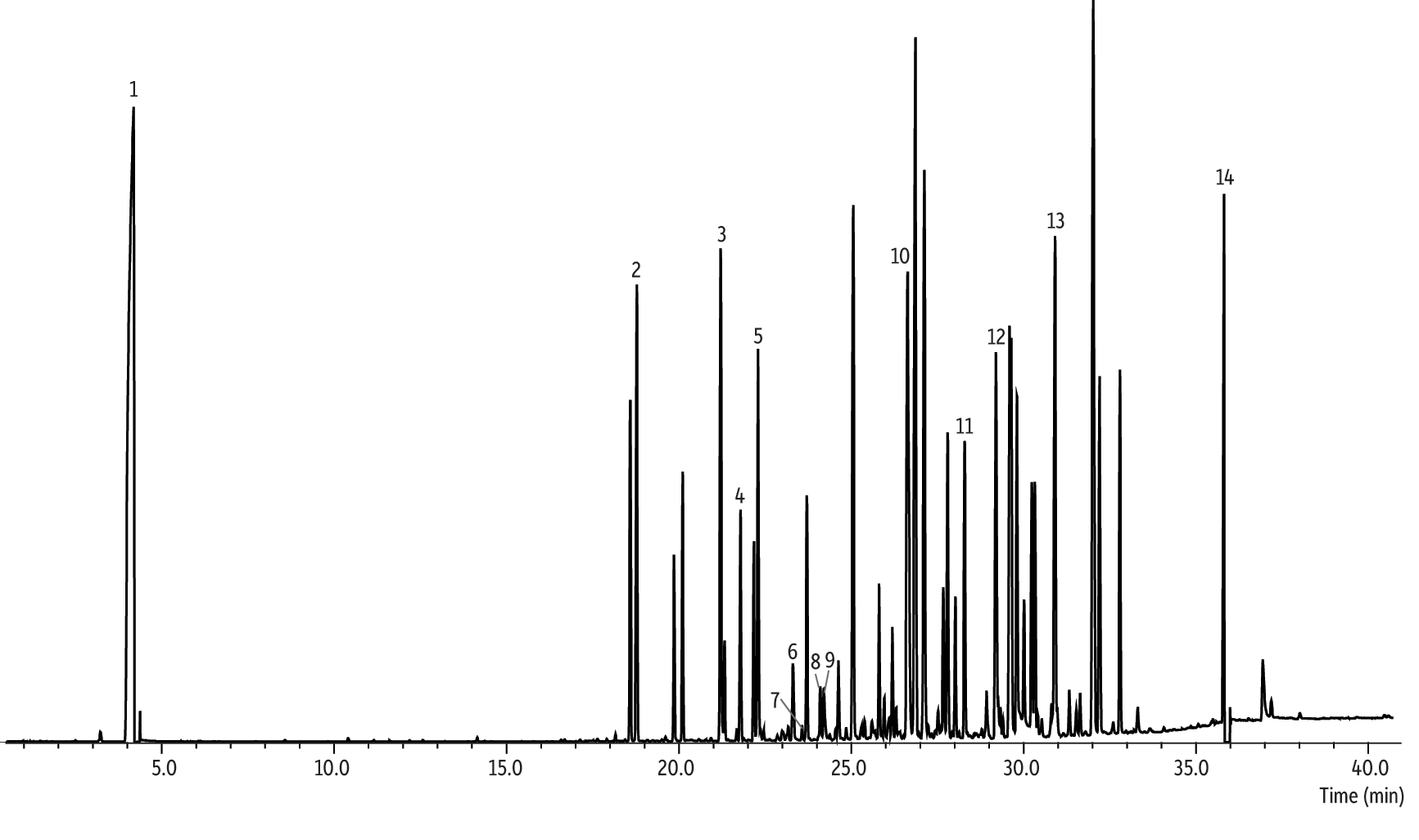

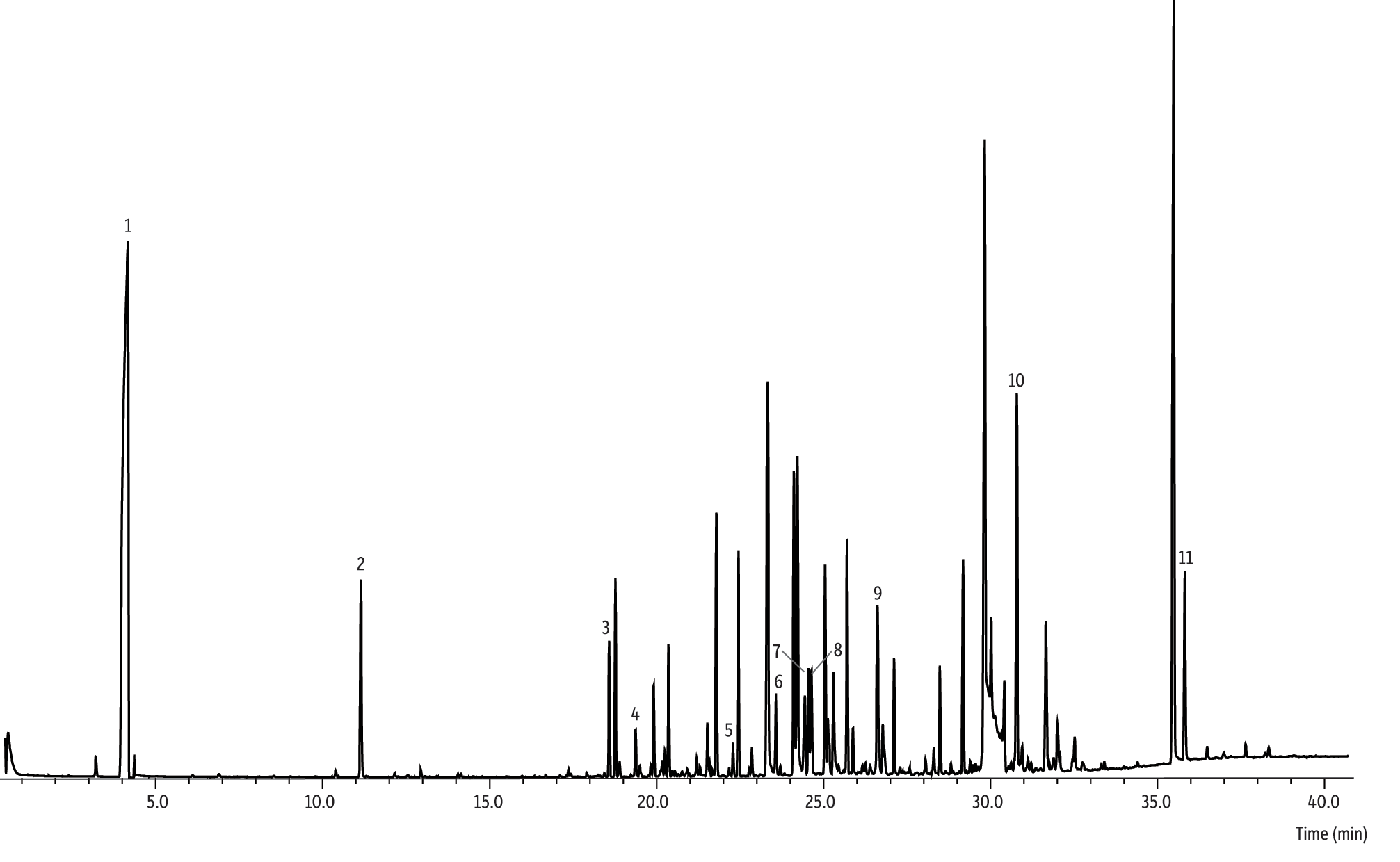

Materials containing fragrances, such as personal care products and perfumes, can be challenging to analyze by GC-MS due to their complex nature. Manufacturers analyze these difficult mixtures for quality control and stability purposes as well as during formulation. Because these mixtures contain a diverse range of compounds at varying concentrations, a stationary phase that offers good selectivity and excellent resolution for a wide range of analytes, high inertness, and low bleed for low-level analysis is necessary. The Stabilwax-MS column provides excellent separation of the alcohols, glycols, and terpenes in a commercial perfume sample analyzed by GC-MS in Figure 3.

Figure 3: Fragrance Allergens and Common Compounds in Commercial Perfume Separated on a Stabilwax-MS Column

Commercial Perfume A

GC_GN1161

GC_GN1161

* Denotes fragrance allergen or suspected allergen

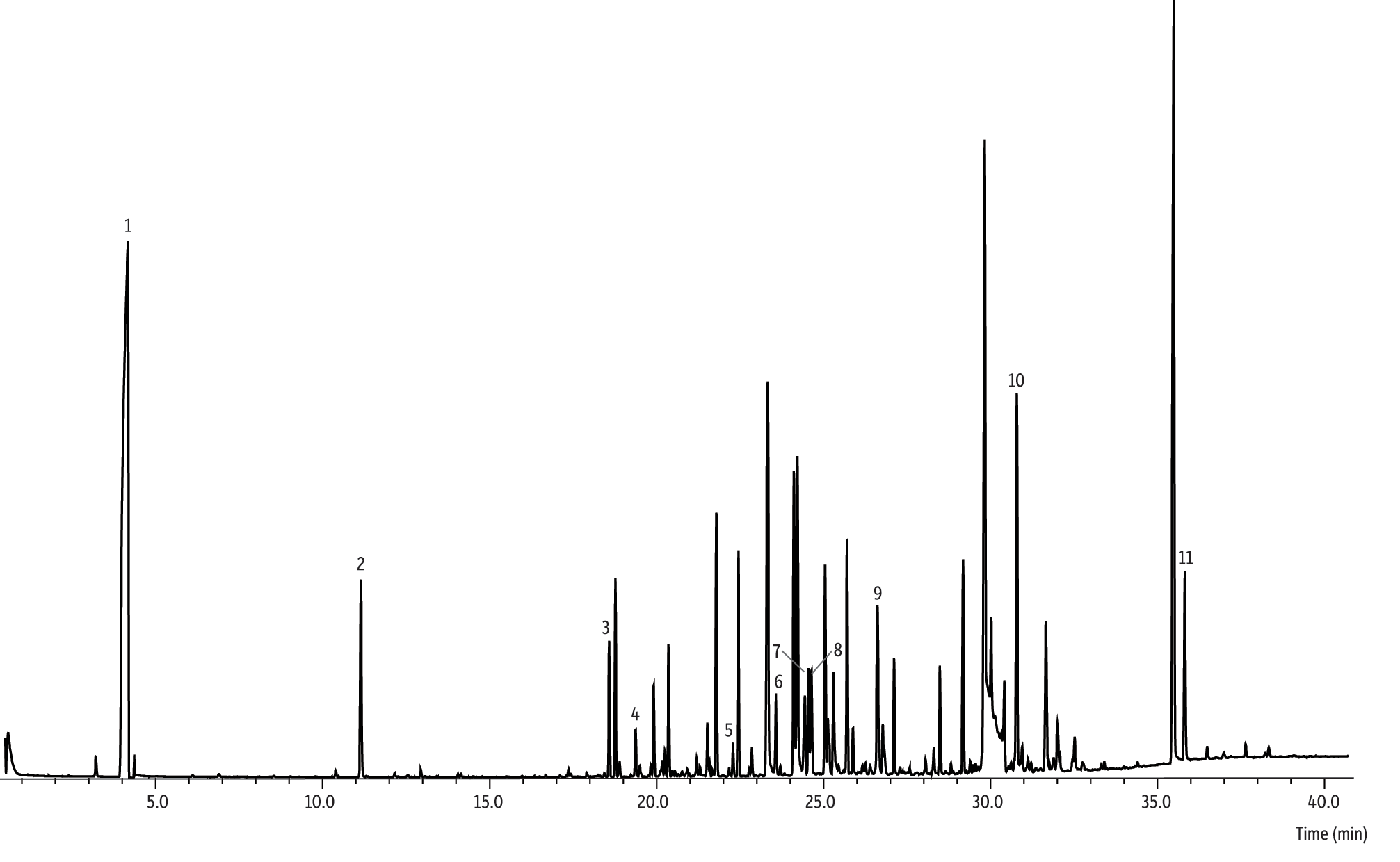

Commercial Perfume B

GC_GN1162

GC_GN1162

* Denotes fragrance allergen or suspected allergen; third isomer of dipropylene glycol not identified.

| Stabilwax-MS, 30 m, 0.25 mm ID, 0.25 µm (cat.# 10673) |

|

| Neat |

| 1 µL split (split ratio 200:1) |

| Premium 3.5 mm single taper w/wool (cat.# 23322) |

| 250 °C |

| 35 °C (hold 5 min) to 250 °C at 7 °C/min (hold 5 min) |

| 36 cm/sec |

| MS |

| Scan |

|

| Group | Start Time

(min) | Scan Range

(amu) | Scan Rate

(scans/sec) |

|---|

| 1 | 0 | 40-550 | 2 |

|

| 260 °C |

| Quadrupole |

| 250 °C |

| 70 eV |

| 0.5 min |

| EI |

Flavor and Food Analysis

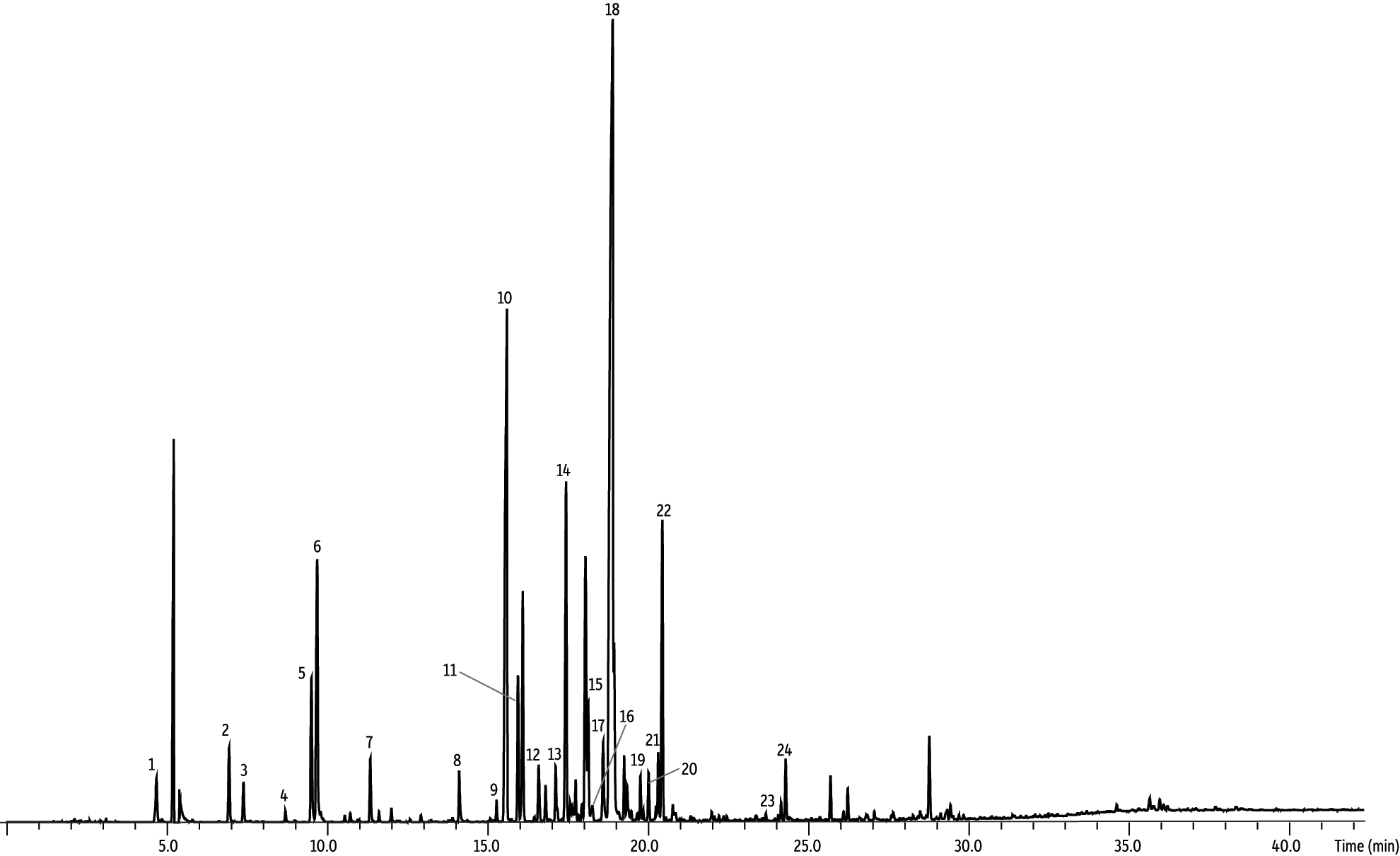

Spearmint Oil

Flavor and food samples contain numerous aromatic compounds; some are naturally present in the raw materials, and some form during processing. GC-MS is extensively used for the analysis of these compounds, which include esters, fatty acids, alcohols, aldehydes, and terpenes. It is also used to detect and measure contaminants from spoilage or adulteration that may be harmful to humans and, therefore, are often controlled by governmental agencies.

Spearmint oil is used in a variety of commercially available products, including food and personal care items. Companies manufacturing materials containing spearmint oil generally control quality by testing for carvone, the main active component that gives spearmint oil its minty flavor. Menthol is also often a target compound as it should be a minor component in spearmint oil but is commonly added as an adulterant. The large menthol peak shown in the spearmint oil sample in Figure 4 indicates that this sample is likely either spearmint oil with menthol added or a different type of oil (e.g., misbranded

peppermint oil). The Stabilwax-MS column provides the required selectivity to give excellent separation of this complex natural sample while exhibiting minimal column bleed at 250 °C by GC-MS.

Alcoholic Beverages

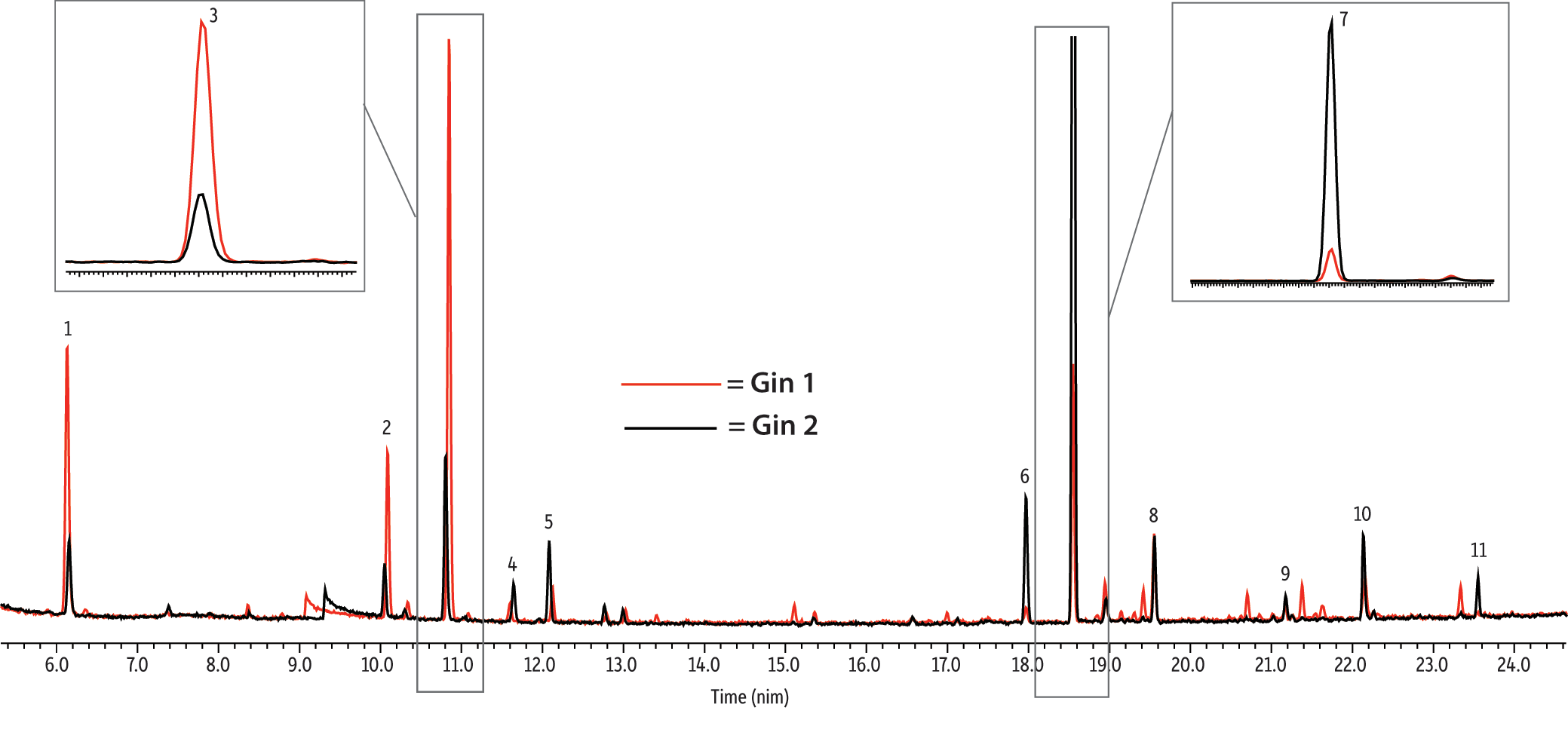

Alcoholic beverages contain a wide range of volatile compounds, including alcohols and short-chain aldehydes, which manufacturers analyze for quality control, authenticity, and brand identification purposes. Gas chromatography can be used to determine these compounds since capillary columns offer efficient separations. Capillary GC is especially useful in the analysis of structurally similar compounds, such as fusel alcohols (i.e., isoamyl alcohol, 4-terpeniol, linalool, geraniol, etc.). The unique polarity of the Stabilwax-MS stationary phase ensures excellent resolution of a range of alcohols and fusel alcohols (also known as fusel oils) as shown in the analysis of a gin sample in Figure 5. The low bleed level obtained with a Stabilwax-MS column permits excellent response and quantitation of the gin volatiles to aid in accurate brand identification.

Industrial Chemicals Analysis

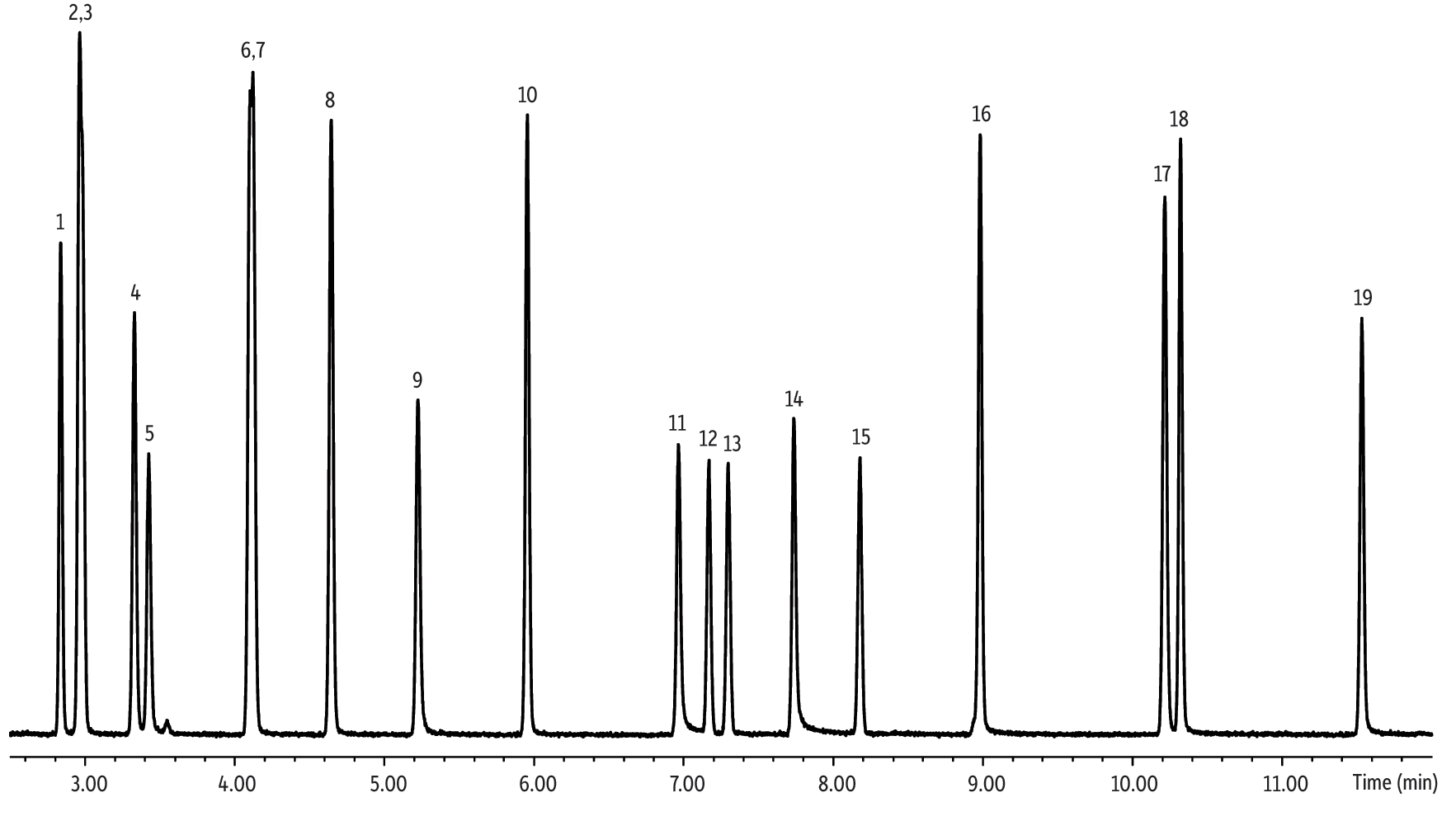

Industrial chemicals and solvents are used in dry cleaning agents, paint thinners, spot removers, perfumes, inks, adhesives, and hundreds of other materials. Many also are used to manufacture polymers, fine chemicals, celluloid cements, and lacquers, such as wood stains and printing applications, as well as in the manufacture of coatings, pharmaceuticals, paints, and packaging material. Analysis of these chemicals and solvents is performed to monitor incoming purity, process control, and disposal (drum waste). Many of the compounds analyzed in Figure 6 are found in packaging samples and industrial hygiene samples. Figure 7 shows excellent separation of chemicals and solvents commonly identified in process control and purity samples. The thermal stability of the Stabilwax-MS column permits fast analysis times for a wide range of compounds in a temperature programmed run and results in low column bleed at 250 °C by GC-MS.

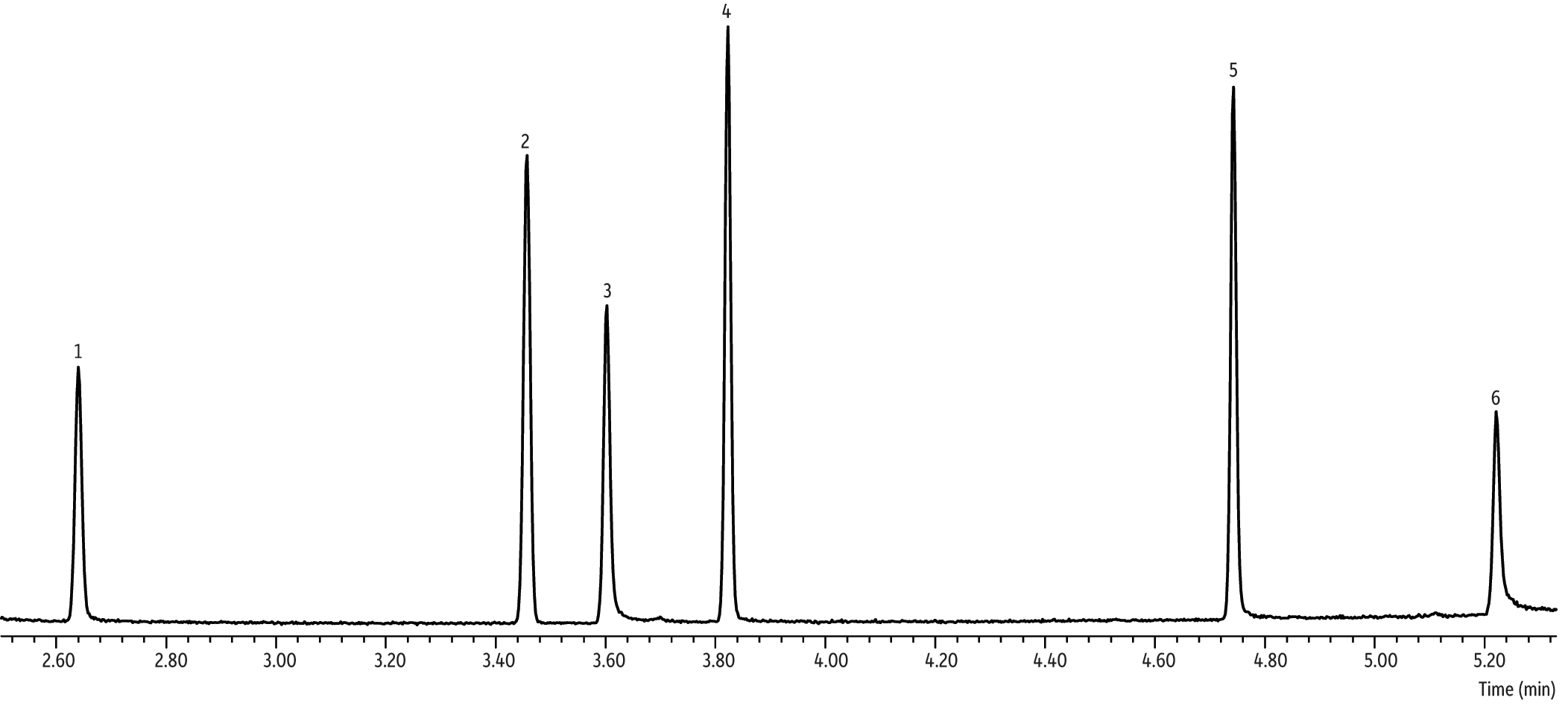

Cleaning Solvent Analysis

Cleaning solvents are used primarily to dissolve organic material. They clean without leaving residue, making them very useful in products, such as glass cleaners. The main criterion for cleaning solvents is water miscibility as the solvent must form a solution with the other water-soluble components. Thus, alcohols and glycols are popular choices. Glycol ethers are made from ethylene and propylene, and they prove to be excellent degreasers, cleaners, and intermediates. There are more than 30 different commonly used glycol ethers with varying technical properties and toxicity profiles. For example, diethylene glycol ethyl ether acetate (EGEEA) has been identified by the European Union as a reproductive toxin and is not manufactured or used in France. In fact, the use of glycol ethers is controlled or has been eliminated in many European countries. The Stabilwax-MS column has excellent selectivity and inertness for alcohols and glycol ethers found in cleaning solvents with the added advantage of good thermal stability. Figure 8 shows baseline resolution is achieved with a fast, 5-minute,temperature-programmed run to 220 °C. The thermal stability of the Stabilwax-MS column would allow a bakeout ramp to 250 °C to remove any high molecular weight contaminants in the cleaning solvents, which would prolong column lifetime and reduce column maintenance.