Column selection(s) for the Renewable Fuel Standard (RFS) Program – Biogas analysis

26 Mar 2024The RFS program seeks to increase energy and fuel production within the USA, while also incentivizing reductions and control of pollutants including sulfurs, siloxanes, greenhouse gases, and an assortment of other toxic compounds1. In turn, these compounds need to be monitored consistently and reliably, which can be difficult in biogas matrices. Biogas is produced from sites such as landfills, sewage treatment plants, pig farms, and cattle farms, where high amounts of methane are produced and can be repurposed for energy, removing emissions from the atmosphere. These sites are notoriously difficult to sample since substrate materials vary dramatically, and can be moist, promoting side-reactions during the sampling and analysis processes. For this reason, a variety of equipment is often necessary to test different compound classes.

To help labs get started and standardize their methods, the RFS Program recommends a variety of regulatory methods related to energy production that can be used to analyze different compounds classes, including ASTM D5504, ASTM D8230, EPA 3C, and EPA 181,2, though many labs also include TO-153 or TO-17. While not specified by the RFS Program, TO-15 and TO-17 are used to monitor toxic gases which are also likely to be present in biogas and may be hazardous to the environment rather than to energy production.

With such a wide range of sample types possible for this program, the specific columns dimensions and selections are likely to vary from industry to industry, but this blog will help identify “starting points” in column-selection for different compound classes.

ASTM D5504-20

Sulfur-containing volatiles compounds are hazards to both the environment and combustion equipment. Hydrogen sulfide, specifically, is a very reactive compound which can readily decompose to H2SO4, poisoning catalysts or corroding biogas engine and turbines4. Other potential degradation byproducts such as sulfur dioxide and trioxide are environmentally hazardous4. This compound is monitored primarily to determine the cost-benefit of using the biogas, where companies can determine how much wear and tear there may be on the equipment, prior to burning.

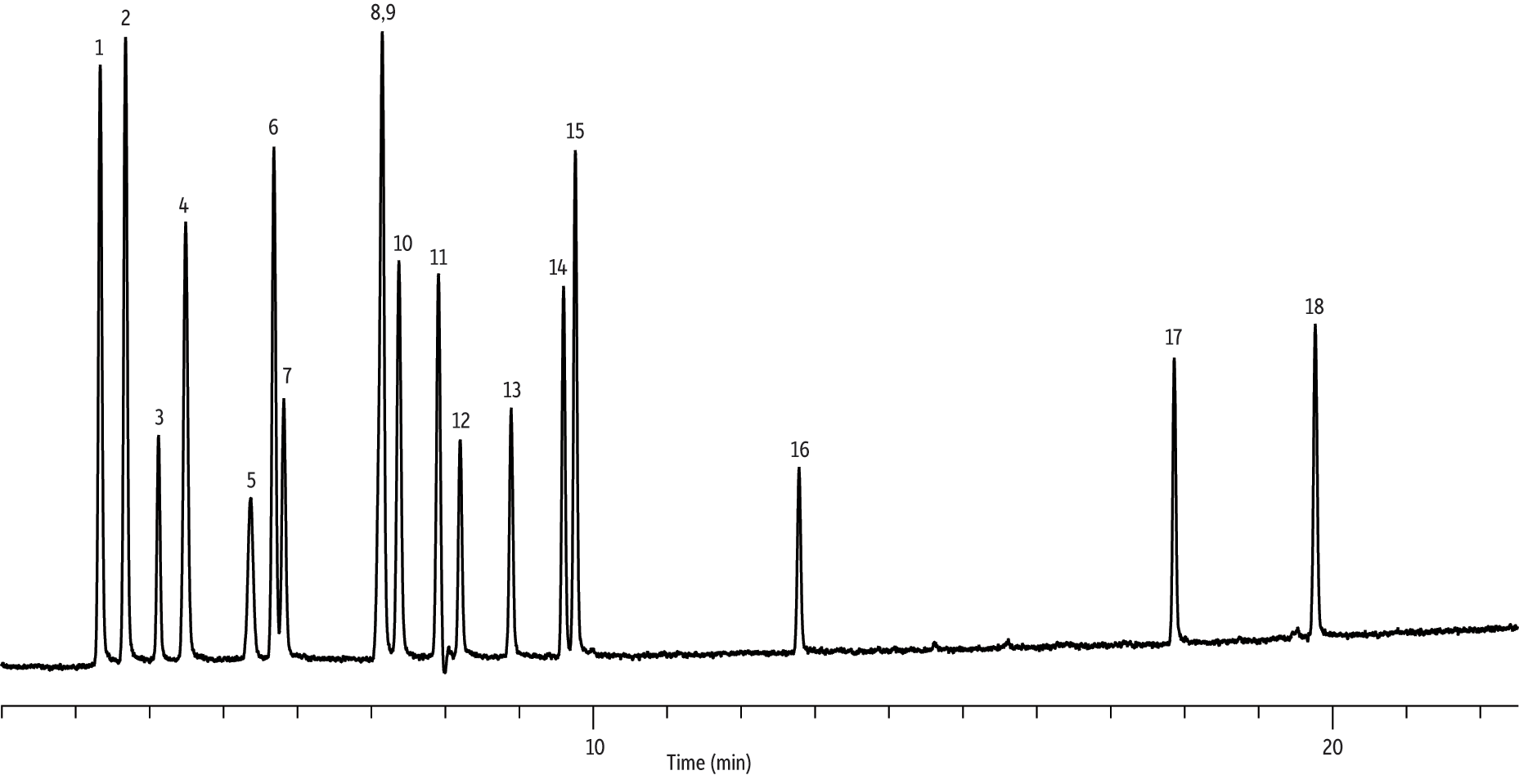

ASTM D5504-20 recommends a 60m x 0.53mmID PDMS phase column5, such as Restek’s Rtx-1, though shorter, narrower ID columns have been demonstrated to work as well, with slightly lower sample capacity. The ASTM method shows an example of retention times possible using a 30m x 0.32mmID x 4µm equivalent to Restek’s Rtx-1 (cat.# 10198), suggesting it is a good starting point. Below is an example method showing separation of some sulfur compounds on the Rtx-1:

| Peaks | Conc. (µg/mL) | |

|---|---|---|

| 1. | Ethyl mercaptan | 100 |

| 2. | Dimethyl sulfide | 100 |

| 3. | Carbon disulfide | 20 |

| 4. | Isopropyl mercaptan | 100 |

| 5. | t-Butyl mercaptan | 50 |

| 6. | n-Propyl mercaptan | 100 |

| 7. | Ethyl methyl sulfide | 50 |

| 8. | sec-Butyl mercaptan | 50 |

| 9. | Thiophene | 100 |

| Peaks | Conc. (µg/mL) | |

|---|---|---|

| 10. | Isobutyl mercaptan | 100 |

| 11. | Diethyl sulfide | 75 |

| 12. | n-Butyl mercaptan | 50 |

| 13. | Dimethyl disulfide | 20 |

| 14. | 2-Methylthiophene | 75 |

| 15. | 3-Methylthiophene | 100 |

| 16. | Diethyl disulfide | 20 |

| 17. | Benzothiophene | 75 |

| 18. | 3-Methylbenzothiophene | 100 |

| Column | Rtx-1, 30 m, 0.32 mm ID, 4.00 µm (cat.# 10198) |

|---|---|

| Standard/Sample | ASTM D5623 standards 1 & 2 from DCG Partnership 1, Ltd. |

| Injection | |

| Inj. Vol.: | 0.2 µL split (split ratio 10:1) |

| Liner: | 4 mm ID cup inlet liner with Siltek deactivation |

| Inj. Temp.: | 275 °C |

| Split Vent Flow Rate: | 24 mL/min |

| Oven | |

| Oven Temp.: | 30 °C (hold 2 min) to 200 °C at 10 °C/min (hold 10 min) |

| Carrier Gas | He, constant flow |

| Flow Rate: | 2.4 mL/min |

| Linear Velocity: | 38 cm/sec @ 30 °C |

| Detector | DP SCD @ 800 °C |

|---|---|

| Burner Vacuum: | 363 torr |

| Hydrogen Flow Rate: | 40 mL/min |

| Air Flow Rate: | 60 mL/min |

| Instrument | Agilent 7890B GC |

| Notes | Solvent standard of sulfur components found in gasoline samples utilizing ASTM D5623. |

ASTM D8230-19

Silicon-containing compounds, primarily polysiloxanes, are present primarily landfills and sewage, from sources such as lubricants and hygienic products6. While volatile methyl siloxanes have the potential to be converted to methane for biogas production, polysiloxanes are more likely to be monitored for their potential to damage equipment4,6. Polysiloxanes, when burnt, leave behind abrasive silica dioxide (SiO2) which abrades and blocks equipment. In addition, some polysiloxanes such as D4 (octamethylcyclotetrasiloxane) and D5 (decamethylcyclopentasiloxane) are known to be hazardous to the environment6.

ASTM D8230-19 provides GC-MS, GC-ICP-MS, and GC-AED methodologies for the analysis of silicon-containing volatiles7. While there is no specific column phase recommendation, the method specifies a low bleed column is necessary, either composed of diphenyl dimethyl polysiloxane7 (i.e. Rtx-5) or 1,4- bis(dimethylsiloxy)phenylene di-methyl polysiloxane7 (Rxi-5Sil MS). Column bleed is composed of polysiloxanes which can of course interfere with analysis of polysiloxanes, so column inertness is a top priority.

However, the need for a thick film will work against another critical need – low bleed. A balance therefore must be struck in column dimensions to keep the film thick enough for the necessary retention of volatiles, but thin enough to control bleed. Clark et al., interested in polysiloxanes D4 and D5 in landfill gas, used a 30m x 0.32mmID x 1µm column6, equivalent to the Rxi-5Sil MS (cat.#13654) With Restek’s exceptionally inert Rxi deactivation, this column is a great starting point for your polysiloxane analysis. As an alternative, the Rtx-200 (cat.# 15020) is also well suited to separating polysiloxanes with a unique chemistry that may benefit separation from other components of a mixture.

EPA 3C

Permanent gas analysis is important for understanding the combustion efficiency of biogas. While biogas is primarily methane, there is likely a high presence of other non-combustible gases such as CO2, CO, N2, and O2 which can interfere with energy production efficiency. This is especially important if catalysts are involved for conversation of non-combustible gases to more combustible gases (usually methane), where the presence of certain contaminants may affect catalyst efficiency too.4

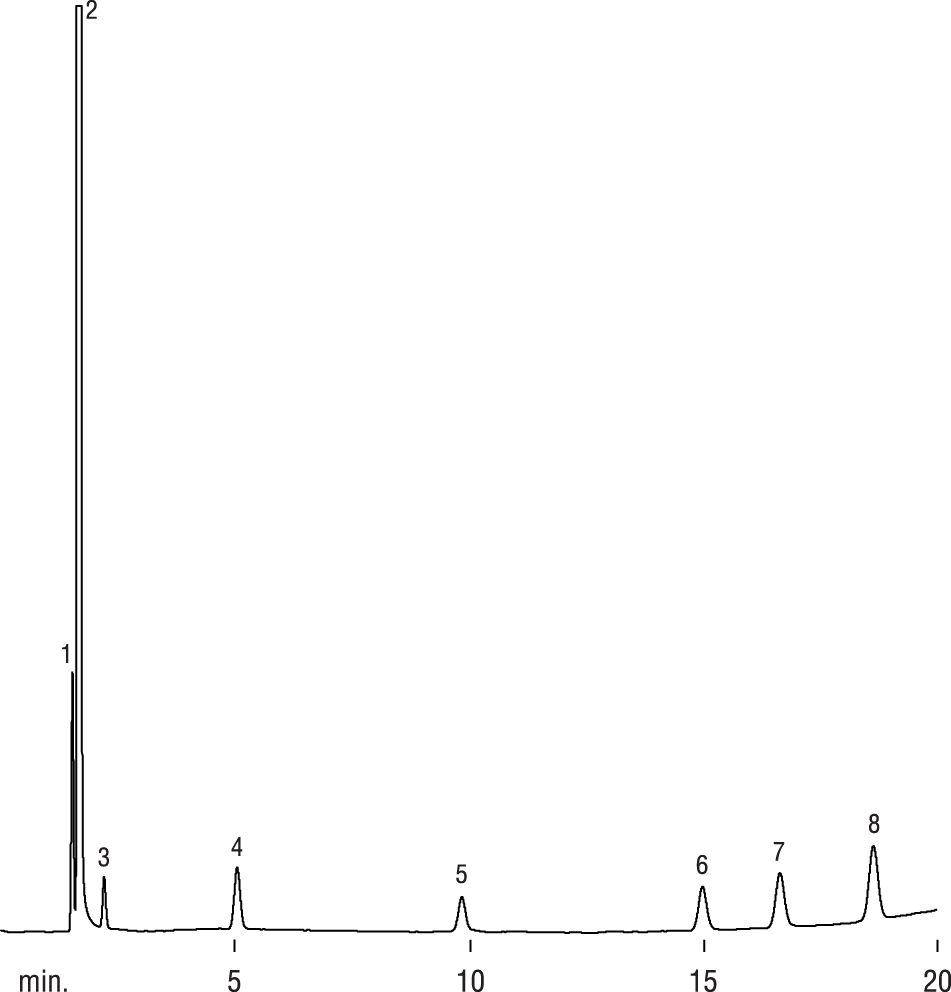

EPA method 3C does not recommend a specific column, but encourages separation of methane, CO2, N2, O2, and “other gas components that may be present in the sample”8. Molecular sieves are prone to adsorption of water and CO2, which is why Restek’s ShinCarbon ST column (cat.# 19808) may be a better option. Below is an example of the separation of permanent gases achievable on the ShinCarbon ST.

| Peaks | |

|---|---|

| 1. | Oxygen |

| 2. | Nitrogen |

| 3. | Carbon monoxide |

| 4. | Methane |

| 5. | Carbon dioxide |

| 6. | Acetylene |

| 7. | Ethylene |

| 8. | Ethane |

| Column | 100/120 mesh, ShinCarbon ST, 2 m, 1/16 in. OD, 1.0 mm ID (cat.# 19808) |

|---|---|

| Standard/Sample | Permanent gases-C1+C2 hydrocarbons |

| Injection | |

| Inj. Vol.: | 5 µL packed on-column |

| Inj. Temp.: | 100 °C |

| Oven | |

| Oven Temp.: | 40 °C (hold 3 min) to 250 °C at 8 °C/min (hold 10 min) |

| Carrier Gas | He, constant flow |

| Flow Rate: | 10 mL/min |

| Detector | HID @ 200 °C |

|---|

Since CO and CO2 do not burn very well, the addition of a methanizer (cat.# 22650, Agilent GC, USA) may be helpful to improve detection limits relative to a TCD.

EPA 18, TO-15 & TO-17

While considered “minor impurities” in biogas, there is a wide variety volatile organic compounds (VOC’s) that are produced in biogas sites, many of which are hazardous to the environment, equipment, or both. The VOC’s are produced either from waste itself (ex: solvents) or from the anaerobic breakdown of waste. Since the waste substrate is highly variable, the compounds produced are also highly variable, which means analytical methods need to be flexible as well. It is well established that biogas sites contain hazardous solvents such benzene and vinyl chloride, alongside more benign malodorous compounds like hydrocarbons and oxygenates4,12. To control odor, chlorinated products may be added to landfills, contributing to the generation of hazardous chlorinated halocarbons as well4,13.

Because of the overlap with toxic compounds, EPA Methods 18, TO-15, or TO-17 can be performed. Method 18 is not very specific about compounds or analytical methods (intentionally)9, while TO-15 and TO-17 provide more details for analysts to work with10,11. However, TO-15 and TO-17 do not include all compounds that may be hazardous to biogas equipment, such as terpenes3,12 so methods and equipment may need to be augmented for this wider range of compounds.

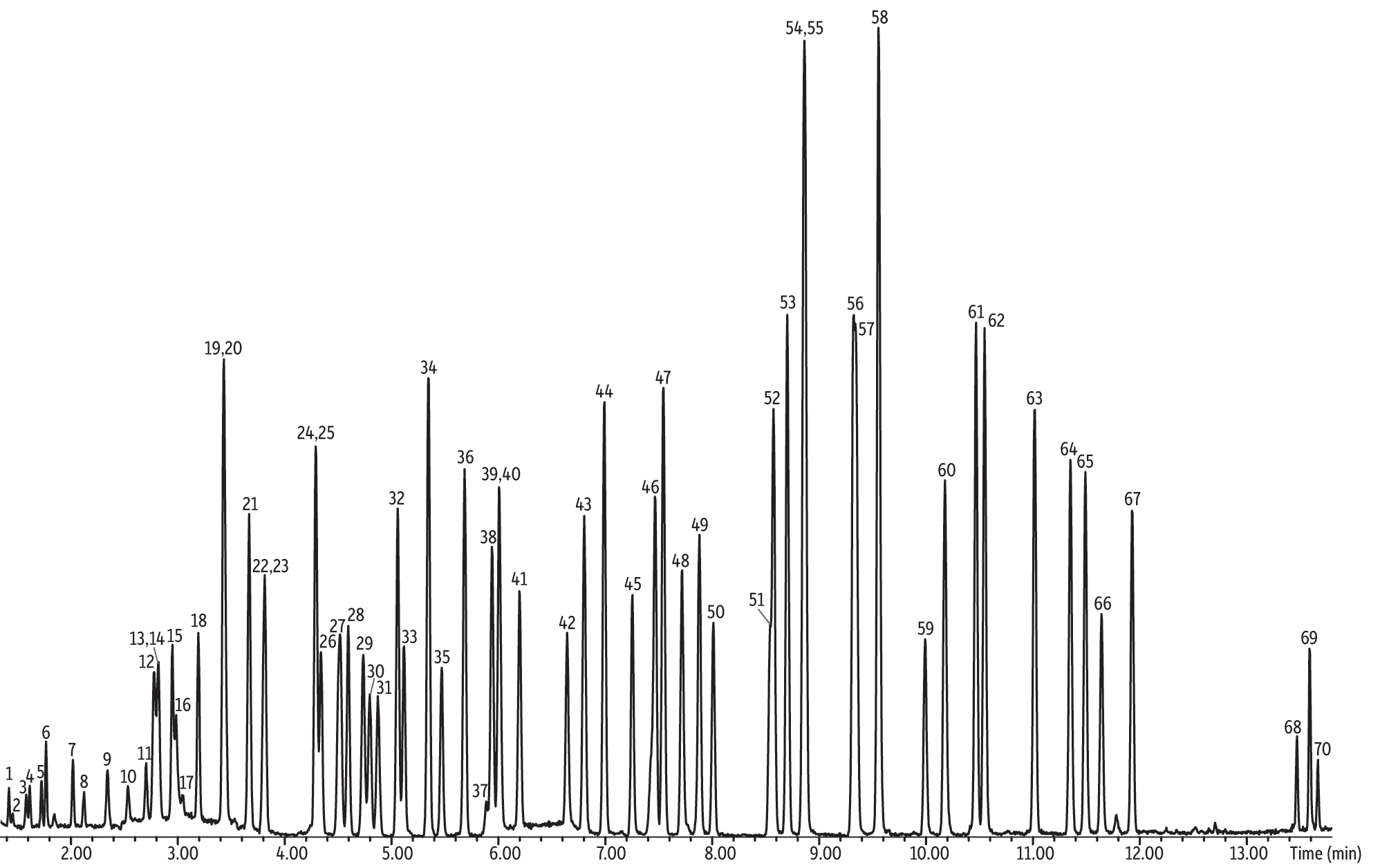

Restek has many options for separating TO-15 compounds, but with the addition of more polar terpenes, the Rxi-624Sil MS is likely the best starting point. Authors Orecchio and Marti both used 60m 624-type columns, such as cat.# 13869 and cat.# 138723,13.

| Peaks | tR (min) | |

|---|---|---|

| 1. | Propylene | 1.42 |

| 2. | Dichlorodifluoromethane (Freon® 12) | 1.46 |

| 3. | 1,2-Dichlorotetrafluoroethane (Freon® 114) | 1.58 |

| 4. | Chloromethane | 1.62 |

| 5. | Vinyl chloride | 1.73 |

| 6. | 1,3-Butadiene | 1.77 |

| 7. | Bromomethane | 2.02 |

| 8. | Chloroethane | 2.12 |

| 9. | Trichlorofluoromethane (Freon® 11) | 2.34 |

| 10. | Ethanol | 2.54 |

| 11. | Acrolein | 2.71 |

| 12. | 1,1-Dichloroethene | 2.78 |

| 13. | 1,1,2-Trichlorotrifluoroethane (Freon® 113) | 2.80 |

| 14. | Acetone | 2.82 |

| 15. | Carbon disulfide | 2.95 |

| 16. | Isopropyl alcohol | 2.99 |

| 17. | Acetonitrile (contaminant) | 3.05 |

| 18. | Methylene chloride | 3.20 |

| 19. | trans-1,2-Dichloroethene | 3.43 |

| 20. | Methyl tert-butyl ether (MTBE) | 3.44 |

| 21. | Hexane | 3.67 |

| 22. | 1,1-Dichloroethane | 3.80 |

| 23. | Vinyl acetate | 3.82 |

| Peaks | tR (min) | |

|---|---|---|

| 24. | 2-Butanone (MEK) | 4.29 |

| 25. | cis-1,2-Dichloroethene | 4.29 |

| 26. | Ethyl acetate | 4.34 |

| 27. | Bromochloromethane (IS) | 4.50 |

| 28. | Tetrahydrofuran | 4.52 |

| 29. | Chloroform | 4.60 |

| 30. | 1,1,1-Trichloroethane | 4.74 |

| 31. | Cyclohexane | 4.80 |

| 32. | Carbon tetrachloride | 4.88 |

| 33. | Benzene | 5.06 |

| 34. | 1,2-Dichloroethane | 5.12 |

| 35. | Heptane | 5.35 |

| 36. | 1,4-Difluorobenzene (IS) | 5.47 |

| 37. | Trichloroethylene | 5.69 |

| 38. | 1,2-Dichloropropane | 5.94 |

| 39. | Methyl methacrylate | 6.01 |

| 40. | 1,4-Dioxane | 6.02 |

| 41. | Bromodichloromethane | 6.20 |

| 42. | cis-1,3-Dichloropropene | 6.64 |

| 43. | 4-Methyl-2-pentanone (MIBK) | 6.80 |

| 44. | Toluene | 6.99 |

| 45. | trans-1,3-Dichloropropene | 7.26 |

| 46. | 1,1,2-Trichloroethane | 7.47 |

| Peaks | tR (min) | |

|---|---|---|

| 47. | Tetrachloroethene | 7.55 |

| 48. | 2-Hexanone (MBK) | 7.72 |

| 49. | Dibromochloromethane | 7.88 |

| 50. | 1,2-Dibromoethane | 8.01 |

| 51. | Chlorobenzene-d5 (IS) | 8.54 |

| 52. | Chlorobenzene | 8.58 |

| 53. | Ethylbenzene | 8.71 |

| 54. | m-Xylene | 8.87 |

| 55. | p-Xylene | 8.87 |

| 56. | o-Xylene | 9.32 |

| 57. | Styrene | 9.35 |

| 58. | Bromoform | 9.56 |

| 59. | 4-Bromofluorobenzene* | 9.99 |

| 60. | 1,1,2,2-Tetrachloroethane | 10.18 |

| 61. | 4-Ethyltoluene | 10.47 |

| 62. | 1,3,5-Trimethylbenzene | 10.55 |

| 63. | 1,2,4-Trimethylbenzene | 11.02 |

| 64. | 1,3-Dichlorobenzene | 11.35 |

| 65. | 1,4-Dichlorobenzene | 11.49 |

| 66. | Benzyl chloride | 11.65 |

| 67. | 1,2-Dichlorobenzene | 11.93 |

| 68. | 1,2,4-Trichlorobenzene | 13.47 |

| 69. | Hexachlorobutadiene | 13.59 |

| 70. | Naphthalene | 13.67 |

| Column | Rxi-624Sil MS, 30 m, 0.32 mm ID, 1.80 µm (cat.# 13870) |

|---|---|

| Standard/Sample | TO-15 65 component mix (cat.# 34436) |

| TO-14A internal standard/tuning mix (cat.# 34408) | |

| Diluent: | Nitrogen |

| Conc.: | 10.0 ppbv 200 cc injection |

| Injection | Direct |

| Oven | |

| Oven Temp.: | 32 °C (hold 1 min) to 150 °C at 11 °C/min to 230 °C at 33 °C/min |

| Carrier Gas | He, constant flow |

| Flow Rate: | 2.0 mL/min |

| Linear Velocity: | 51 cm/sec @ 32 °C |

| Detector | MS |

|---|---|

| Mode: | Scan |

| Transfer Line Temp.: | 230 °C |

| Analyzer Type: | Quadrupole |

| Source Temp.: | 230 °C |

| Quad Temp.: | 150 °C |

| Electron Energy: | 69.9 eV |

| Solvent Delay Time: | 1.0 min |

| Tune Type: | BFB |

| Ionization Mode: | EI |

| Scan Range: | 35 - 250 amu |

| Scan Rate: | 3.32 scans/sec |

| Instrument | HP6890 GC & 5973 MSD |

| Acknowledgement | Nutech |

Alternative columns that may be suitable, depending on the specific compounds being investigated, include Rxi-1ms, Rxi-5Sil MS, and Rtx-VMS. To help with the selection, a variety of compounds that may be of interest are included in Restek’s ProEZGC libraries. Column phases, dimensions, and oven parameters can be adjusted to determine which column is best for your specific VOC analysis.

Additional resources:

Alan Sensue has additional recommendations for sampling equipment related to your biogas analysis: Sampling and analysis of landfill gas biogas an overview (restek.com)

References:

- Renewable fuel standards Program: Renewable Fuel Standard Program | US EPA

- 40 CFR Parts 80 and 1090 (pg 44535): https://www.govinfo.gov/content/pkg/FR-2023-07-12/pdf/2023-13462.pdf

- Orecchio et al.: https://doi.org/10.3390/ijerph14020195

- Braganca et al.: https://doi.org/10.1016/j.biombioe.2020.105878

- ASTM D5504: D5504 Standard Test Method for Determination of Sulfur Compounds in Natural Gas and Gaseous Fuels by Gas Chromatography and Chemiluminescence (astm.org)

- Clark et al.: https://doi.org/10.1139/l2012-051

- ASTM D8230: D8230 Standard Test Method for Measurement of Volatile Silicon-Containing Compounds in a Gaseous Fuel Sample Using Gas Chromatography with Spectroscopic Detection (astm.org)

- EPA 3C: METHOD 3C—DETERMINATION OF CARBON DIOXIDE, METHANE, NITROGEN, AND OXYGEN FROM STATIONARY SOURCES (epa.gov)

- EPA 18: method_18_0.pdf (epa.gov)

- EPA TO-15: https://www.epa.gov/sites/default/files/2019-12/documents/to-15a_vocs.pdf

- EPA TO-17: Method TO-17 - Determination of Volatile Organic Compounds in Ambient Air Using Active Sampling Onto Sorbent Tubes (epa.gov)

- Duan et al.: https://doi.org/10.1016/j.wasman.2020.09.015

- Marti et al.: https://doi.org/10.1016/j.apgeochem.2014.06.018