Alternative Carrier Gases for ASTM D7213 Simulated Distillation Analysis

Introduction

Crude oil consists of thousands of different hydrocarbons that span a very wide volatility range. In order to efficiently produce quality finished products, refineries depend on simulated distillation (SimDist) analyses to characterize the composition of their crude feedstock prior to processing. SimDist is a gas chromatography (GC) technique that allows fast, reproducible, and easily automated determination of boiling point distribution of crude oil samples.

Until recently, helium has been the only accepted gas for ASTM SimDist analysis. The ASTM SimDist committee now has approved the use of alternative carrier gases—nitrogen and hydrogen—for SimDist analyses. This article will explore alternative carrier gas options for SimDist analyses and discuss their various benefits and drawbacks.

Nitrogen or Hydrogen: Both are Sustainable Alternatives

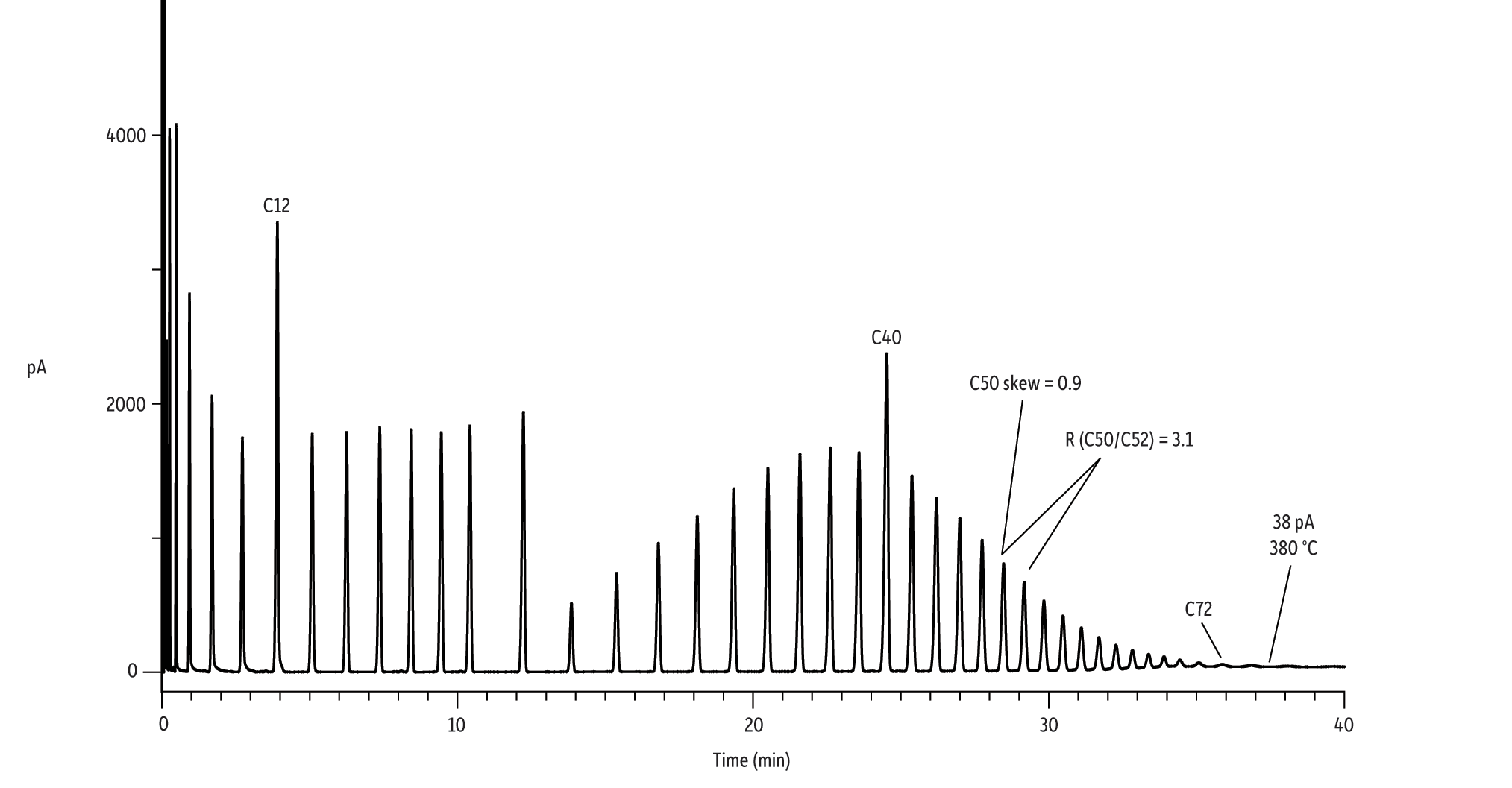

Alternative carrier gases for SimDist analysis are explored in this article in the context of ASTM Method D7213. This method was developed to cover boiling range distribution of petroleum products and fractions such as medium and heavy naphtha, kerosene, jet fuels, and diesel, which have initial boiling points greater than 100 °C and final boiling points less than 615 °C, ranging from C5-C60. ASTM D7213 specifies that in order to successfully conduct the analysis, resolution between C50 and C52 must be greater than 1 and not more than 10. Additionally, peak symmetry or "skewness" must be greater than 0.5 and must not exceed 2. A traditional ASTM D7213 analysis using helium carrier gas is shown in Figure 1.

Figure 1 shows that Restek’s 5 m x 0.53 mm x 0.88 µm MXT-1HT SimDist column (cat.# 70131) has excellent sample capacity, ensuring peaks do not exceed the method skewness requirements. Extremely low column bleed results in accurate and reproducible retention times for the later eluting hydrocarbons.

Figure 1: All ASTM Method D7213 requirements are met using an MXT-1HT SimDist Column under typical conditions using helium as the carrier gas.

| Column | MXT-1HT SimDist, 5 m, 0.53 mm ID, 0.88 µm (cat.# 70131) |

|---|---|

| Standard/Sample | Retention time standard for D7213 (C5-C72), Separation Systems, Inc. |

| Diluent: | Carbon disulfide |

| Conc.: | 1 wt% |

| Injection | |

| Inj. Vol.: | 1 µL PTV on column |

| Liner: | Premium 1.7 mm ID on-column inlet liner (cat.# 23430) |

| Inlet Temp. Program: | 90 °C to 380 °C at 20 °C/min |

| Oven | |

| Oven Temp.: | 40 °C to 380 °C at 10 °C/min (hold 10 min) |

| Carrier Gas | He, constant flow |

| Flow Rate: | 12 mL/min |

| Detector | FID @ 390 °C |

|---|---|

| Make-up Gas Flow Rate: | 18 mL/min |

| Make-up Gas Type: | N2 |

| Hydrogen flow: | 43 mL/min |

| Air flow: | 400 mL/min |

| Instrument | Agilent 7890B GC |

Nitrogen

Nitrogen is a very good alternative carrier gas because it is readily available in cylinders or from nitrogen generators and has no explosive properties. Additionally, nitrogen is the most efficient carrier gas in comparison to helium and hydrogen when operated at their respective optimum velocities.

Efficiency directly relates to peak width—more efficient separations will have narrower peaks with higher resolution. Figure 2 shows van Deemter curves for hydrogen, nitrogen, and helium. The y-axis measures “height equivalent to a theoretical plate” (HETP) and higher efficiency occurs at lower HETP values. Therefore, efficiency is maximized at the minimum point of each van Deemter curve. The x-axis measures carrier gas linear velocity, thus, Figure 2 shows that the separation efficiency with each carrier gas differs depending on linear velocity.

Figure 2: Van Deemter curves for hydrogen, helium, and nitrogen. Optimum efficiency is obtained at the linear velocity corresponding to the minimum point on each curve.

Nitrogen has the lowest minimum van Deemter curve value; however, this minimum occurs at a very slow linear velocity. This means that even though very good separations can be achieved using nitrogen carrier gas, the analysis time will be longer compared to using helium or hydrogen when operated at their respective optimum velocities. Increasing the linear velocity in order to decrease the analysis time when using nitrogen will result in a rapid loss of column efficiency.

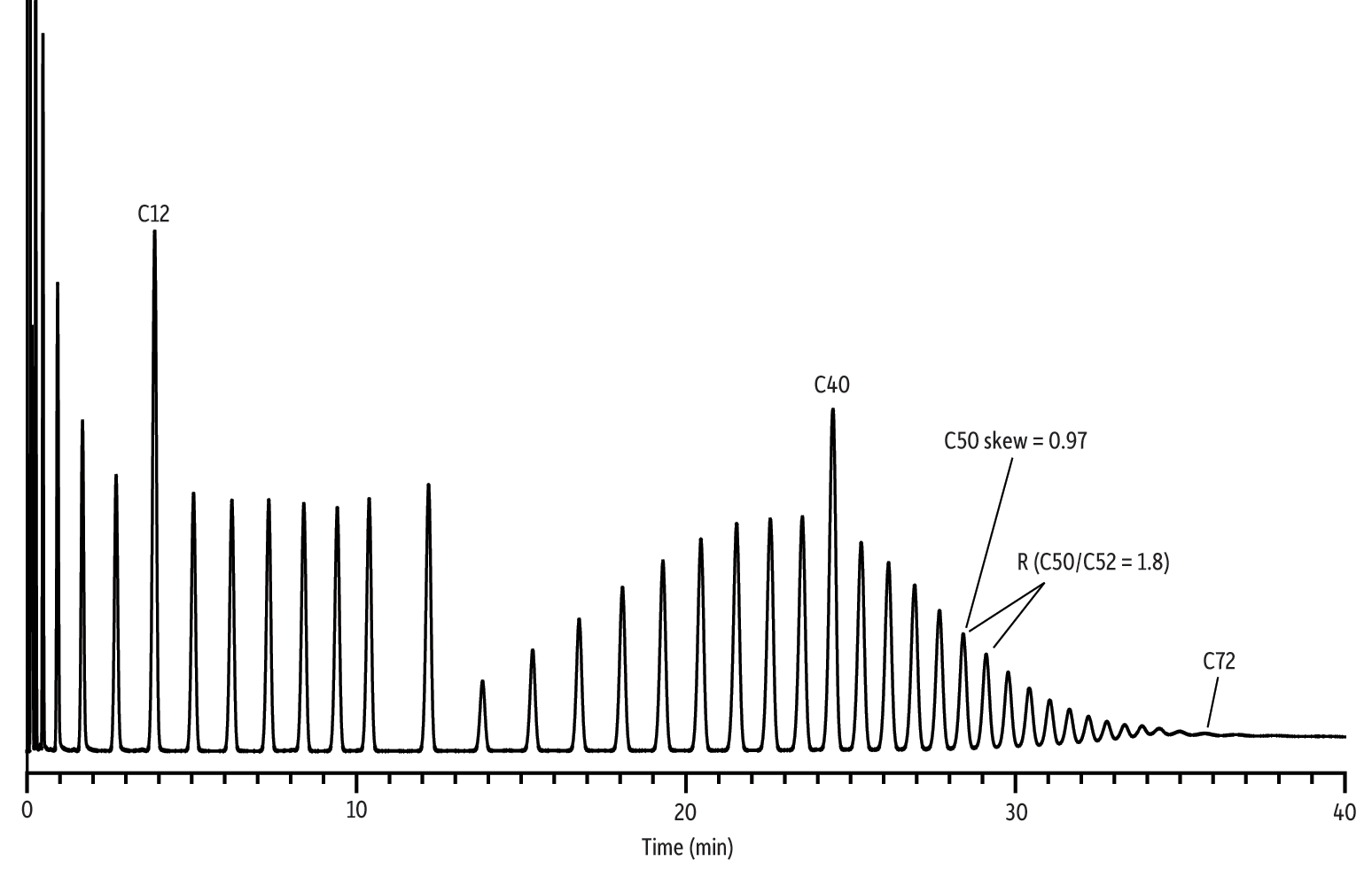

The MXT-1HT SimDist column was tested for ASTM D7213 performance using nitrogen carrier gas. If nitrogen were employed at its optimum linear velocity, the resulting method would be much longer than the original method. Instead of translating methods to yield maximum efficiency, many nitrogen users simply replace helium with nitrogen, keeping all other method parameters the same (e.g., carrier gas linear velocity and oven program). Even though some efficiency is lost when employing nitrogen as a carrier gas without flow optimization, Restek’s MXT-1HT SimDist column offers enough efficiency to easily meet ASTM requirements for resolution between C50 and C52. Due to the loss of efficiency, peak heights are lower, meaning some response may be lost, but the low-bleed performance of this column allows for detection of broader peaks at lower levels, and baseline resolution of high molecular weight hydrocarbons is possible (Figure 3).

Figure 3: Even with nitrogen as the carrier gas, MXT-1HT SimDist columns provide adequate resolution to meet ASTM Method D7213 requirements.

| Column | MXT-1HT SimDist, 5 m, 0.53 mm ID, 0.88 µm (cat.# 70131) |

|---|---|

| Standard/Sample | Retention time standard for D7213 (C5-C72), Separation Systems, Inc. |

| Diluent: | Carbon disulfide |

| Conc.: | 1 wt% |

| Injection | |

| Inj. Vol.: | 1 µL PTV on column |

| Liner: | Premium 1.7 mm ID on-column inlet liner (cat.# 23430) |

| Inlet Temp. Program: | 90 °C to 380 °C at 20 °C/min |

| Oven | |

| Oven Temp.: | 40 °C to 380 °C at 10 °C/min (hold 10 min) |

| Carrier Gas | N2, constant flow |

| Flow Rate: | 11.9 mL/min |

| Detector | FID @ 390 °C |

|---|---|

| Make-up Gas Flow Rate: | 18 mL/min |

| Make-up Gas Type: | N2 |

| Hydrogen flow: | 43 mL/min |

| Air flow: | 400 mL/min |

| Instrument | Agilent 7890B GC |

Hydrogen

Hydrogen is comparable in price to nitrogen, and it has the additional advantage of being easy to generate. In contrast to nitrogen, hydrogen has a faster optimum linear velocity than helium (Figure 2). This means that with proper translation, methods can be shortened by approximately 25% when switching to hydrogen carrier gas.

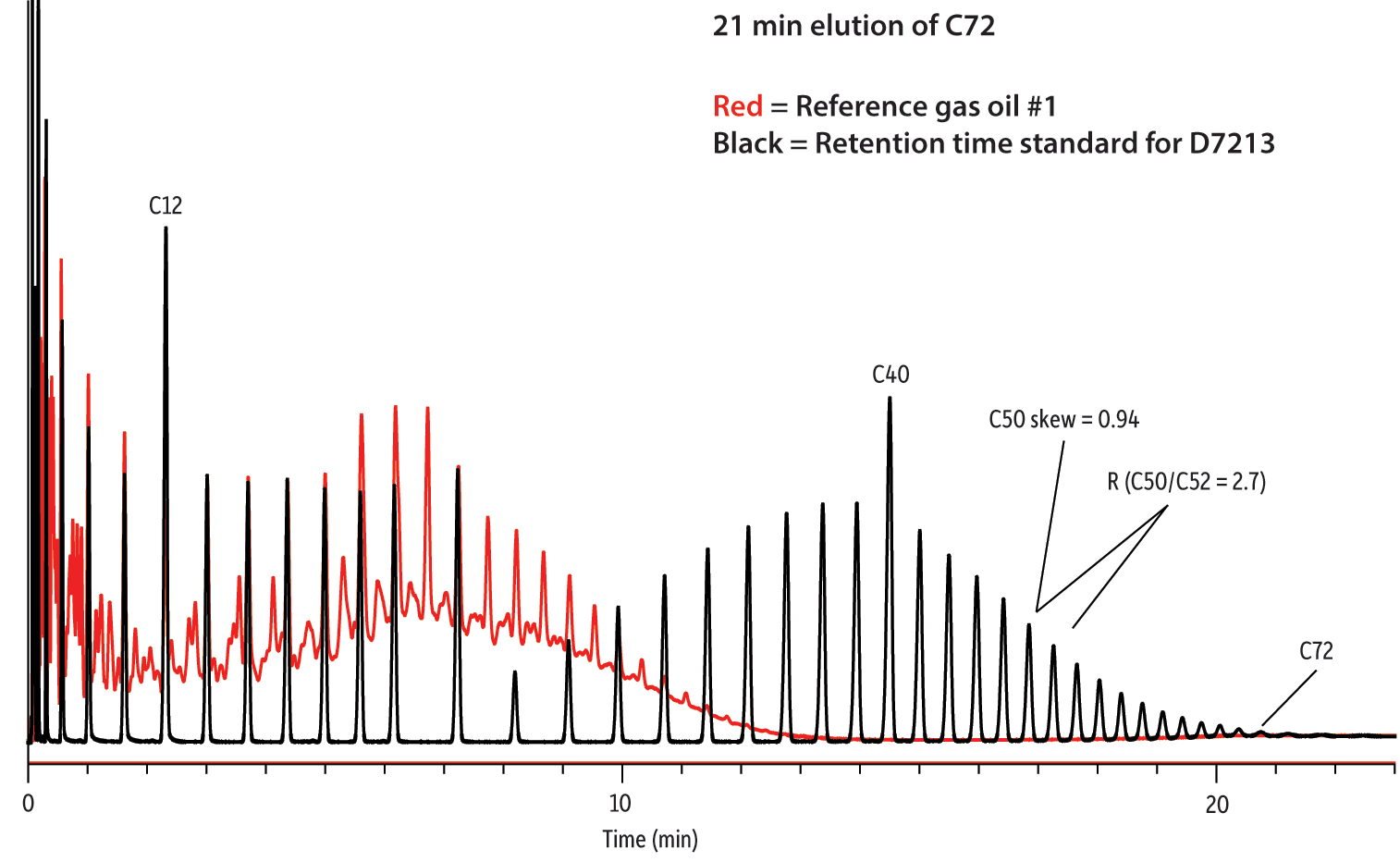

Restek’s EZGC method translator was used in custom mode to translate ASTM D7213 from helium to hydrogen carrier gas. Since the optimum linear velocity of hydrogen is faster than that of helium, changing the linear velocity to match the optimum for hydrogen will result in a faster analysis. However, the oven ramp rates must be changed proportionally in order to preserve the chromatography of the original method. Figure 4 shows the chromatogram generated using hydrogen carrier gas at 20 mL/min with a translated oven program. Elution time of C72 was shortened by 15 minutes (compared to using helium in Figure 1) while maintaining very good resolution between C50 and C52.

Figure 4: Overlay of chromatograms of a qualitative mixture of normal paraffins (C5-C72) and a reference gas oil comparing their boiling point distributions.

| Column | MXT-1HT SimDist, 5 m, 0.53 mm ID, 0.88 µm (cat.# 70131) |

|---|---|

| Standard/Sample | Retention time standard for D7213 (C5-C72), Separation Systems, Inc. |

| Reference gas oil #1 | |

| Injection | |

| Inj. Vol.: | 1 µL PTV on column |

| Liner: | Premium 1.7 mm ID on-column inlet liner (cat.# 23430) |

| Inlet Temp. Program: | 90 °C to 380 °C at 20 °C/min |

| Oven | |

| Oven Temp.: | 40 °C to 380 °C at 16.9 °C/min (hold 5 min) |

| Carrier Gas | H2, constant flow |

| Flow Rate: | 20 mL/min |

| Detector | FID @ 390 °C |

|---|---|

| Make-up Gas Flow Rate: | 25 mL/min |

| Hydrogen flow: | 25 mL/min |

| Air flow: | 400 mL/min |

| Instrument | Agilent 7890B GC |

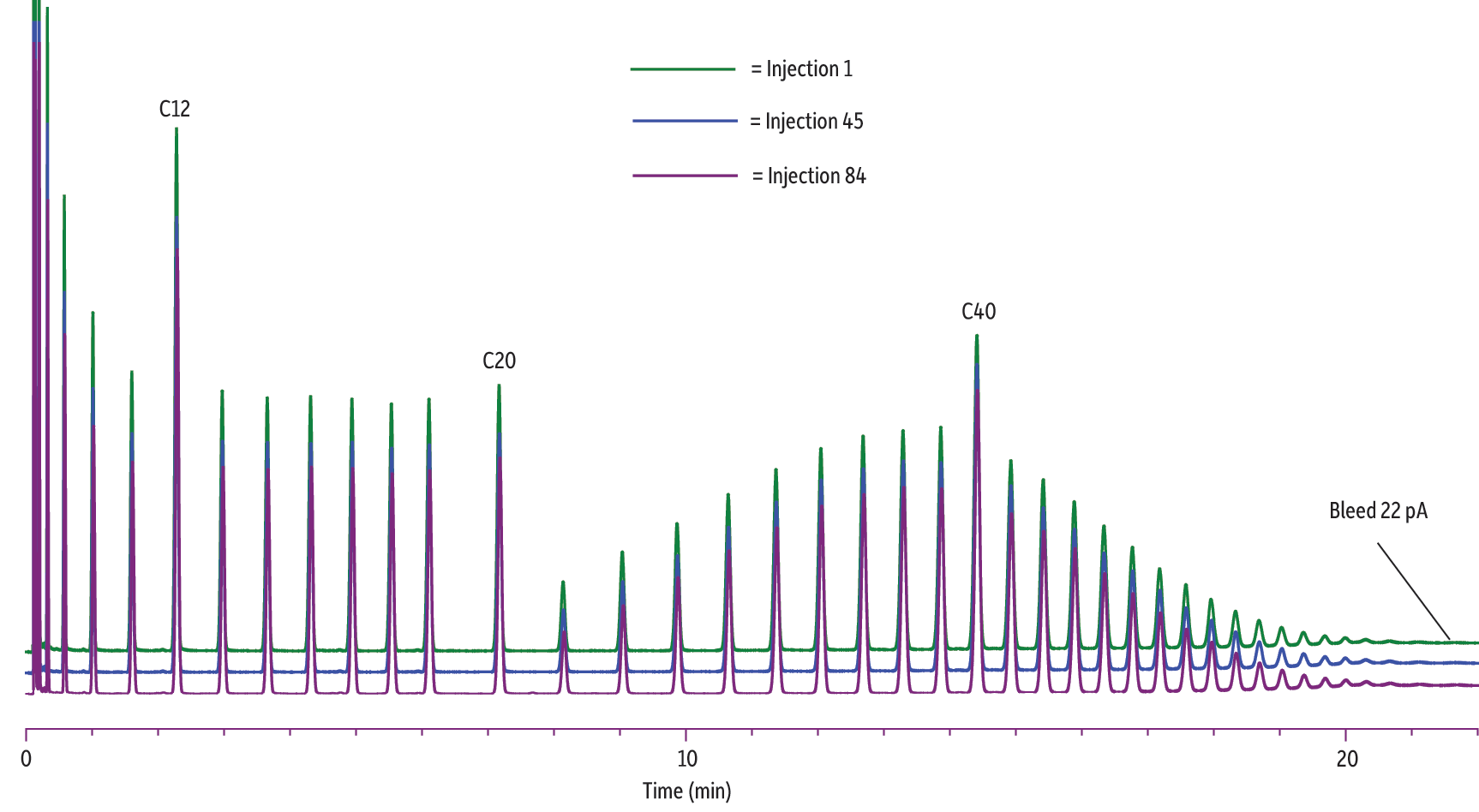

Although hydrogen is affordable and allows the opportunity to significantly shorten analysis time, it is an explosive gas, which causes concern for some laboratories. Additionally, hydrogen is a reducing gas, meaning it is reactive whereas nitrogen and helium are nonreactive. In general, concerns regarding the reactivity of hydrogen revolve around higher temperature analysis of active analytes, but poorly coated metal columns also can be prone to reduction reactions from hydrogen at high temperatures. The MXT-1HT SimDist column shows no decrease in performance over many temperature cycles and CS2 injections using hydrogen carrier gas, indicating a rugged, high-quality column coating (Figure 5, Table I).

Figure 5: Excellent repeatability for C5-C72 hydrocarbons is obtained using the MXT-1HT SimDist column, ensuring consistent performance from injection to injection.

| Column | MXT-1HT SimDist, 5 m, 0.53 mm ID, 0.88 µm (cat.# 70131) |

|---|---|

| Standard/Sample | Retention time standard for D7213 (C5-C72), Separation Systems, Inc. |

| Diluent: | Carbon disulfide |

| Conc.: | 1 wt% |

| Injection | PTV on column |

| Liner: | Premium 1.7 mm ID on-column inlet liner (cat.# 23430) |

| Inlet Temp. Program: | 90 °C to 380 °C at 20 °C/min |

| Oven | |

| Oven Temp.: | 40 °C to 380 °C at 16.9 °C/min (hold 5 min) |

| Carrier Gas | H2, constant flow |

| Flow Rate: | 20 mL/min |

| Detector | FID @ 390 °C |

|---|---|

| Make-up Gas Flow Rate: | 25 mL/min |

| Make-up Gas Type: | N2 |

| Hydrogen flow: | 25 mL/min |

| Air flow: | 400 mL/min |

| Instrument | Agilent 7890B GC |

Table I: Retention time repeatability for selected carbon numbers taken from the GC chromatograms of the C5 to C72 reference standard analyzed in Figure 5.

|

Carbon No. |

Run 1 (min) |

Run 45 (min) |

Run 84 (min) |

% RSD (n=3) |

|

C8 |

0.328 |

0.322 |

0.322 |

1.069 |

|

C10 |

1.023 |

1.013 |

1.011 |

0.633 |

|

C14 |

3.668 |

3.658 |

3.654 |

0.197 |

|

C20 |

7.182 |

7.173 |

7.168 |

0.010 |

|

C28 |

10.654 |

10.646 |

10.641 |

0.062 |

|

C36 |

13.303 |

13.295 |

13.29 |

0.049 |

|

C40 |

14.419 |

14.410 |

14.411 |

0.034 |

|

C50 |

16.776 |

16.772 |

16.767 |

0.027 |

|

C60 |

18.696 |

18.691 |

18.685 |

0.030 |

|

C66 |

19.691 |

19.688 |

19.684 |

0.018 |

Conclusion

Carrier gas changes for SimDist methods, such as ASTM Method D7213, can be easily implemented in your daily process. MXT-1HT SimDist columns offer excellent efficiency so adequate separations can be achieved even when operating at faster-than-optimal linear velocities. In addition, these columns are robust enough to withstand high temperatures and extreme conditions and still provide the low bleed levels needed for accurate boiling point determination analyses. Using MXT-1HT SimDist columns and EZGC method translation software, helium-based SimDist methods can be easily translated to alternative carrier gases while maintaining ASTM Method D7213 requirements.