LC-MS/MS Analysis of Acrylamide in Drinking Water Using Large Volume Injection

- Meet sensitivity requirements without time-consuming sample preconcentration.

- 150 x 3.0 Allure Acrylamide column balances sufficient retention and fast elution.

- 100 µL injection volume increases signal and avoids matrix interferences.

Acrylamide has wide application as a reagent in the synthesis of organic chemicals and as a monomer in the production of polyacrylamide polymers. However, it is also associated with significant health concerns: it can damage the human nervous system, and numerous agencies have listed it as a probable human carcinogen. Individuals can be exposed to acrylamide through consumption of starchy foods that were cooked using high-heat techniques, such as frying or roasting, but much broader population-level exposure can result from contaminated water supplies. This makes the analysis of acrylamide in drinking water an increasing priority for labs worldwide.

In both waste and drinking water treatment, polyacrylamides are used as flocculating agents. Incoming water can have a high concentration of suspended particles, and treatment plants use chemicals to destabilize the suspensions (coagulation) and then cause the destabilized particles to aggregate, forming larger and larger particles that more readily settle out of the water (flocculation). Polyacrylamide-based flocculating agents are particularly effective, but they can release monomeric acrylamide, so in order to be used they must produce only very low levels. Traditionally, acrylamide in water has been calculated from the percentage of residual acrylamide monomer in the polyacrylamide used in flocculation process. However, current liquid chromatography techniques have advanced considerably and now allow the direct analysis of acrylamide in drinking water. Many environmental laboratories are incorporating direct testing and there is particular interest in highly sensitive techniques, such as large volume injection.

Meeting Sensitivity Requirements

The analysis of acrylamide in drinking water is typically done using LC-MS/MS methods, but retaining acrylamide and separating it from matrix components is very challenging using most reversed-phase LC columns. To make the analysis even more difficult, method performance limits for acrylamide in drinking water are very low, and the ppt levels that are generally required can be tough to quantify, especially on older LC-MS/MS instruments.

The first step in meeting sensitivity requirements is using a column with a stationary phase and particle type that provides the right amount of retention for acrylamide, a level that ensures separation from any matrix interferences while still eluting it as quickly as possible. Allure Acrylamide columns have been demonstrated to provide excellent retention characteristics for separating acrylamide from matrix components. They were developed specifically for this analysis and contain particles with a bonded stationary phase that has an affinity for polar molecules and with small pores that will increase the retention of small polar molecules, such as acrylamide.

The second step in obtaining adequate sensitivity is determining which of two commonly used strategies are best for your lab: (1) offline preconcentration using solid phase extraction (SPE), or (2) large volume injections. For labs using SPE preconcentration, a 50 x 2.1 mm Allure Acrylamide column is a good choice. Many labs use large volume injection instead because it can save time, money, and potentially reduce error; however, this approach requires the balance of competing influences. For this purpose, a 150 x 3.0 mm Allure Acrylamide column both provides the necessary capacity and uses an optimal flow rate that is low enough to avoid decreases in MS sensitivity. If you use a column that is too large, the gains in capacity would be negated by either loss of MS sensitivity (if using the column’s optimal flow rate because it is higher than the optimal MS flow rate), or loss of efficiency and time (if operating at the optimal MS flow rate, which is much slower than a larger column’s optimal flow rate). Keep in mind that the inherent sensitivity of your instrument may also, in part, dictate the amount of sample that must be injected.

Minimizing Matrix Interference

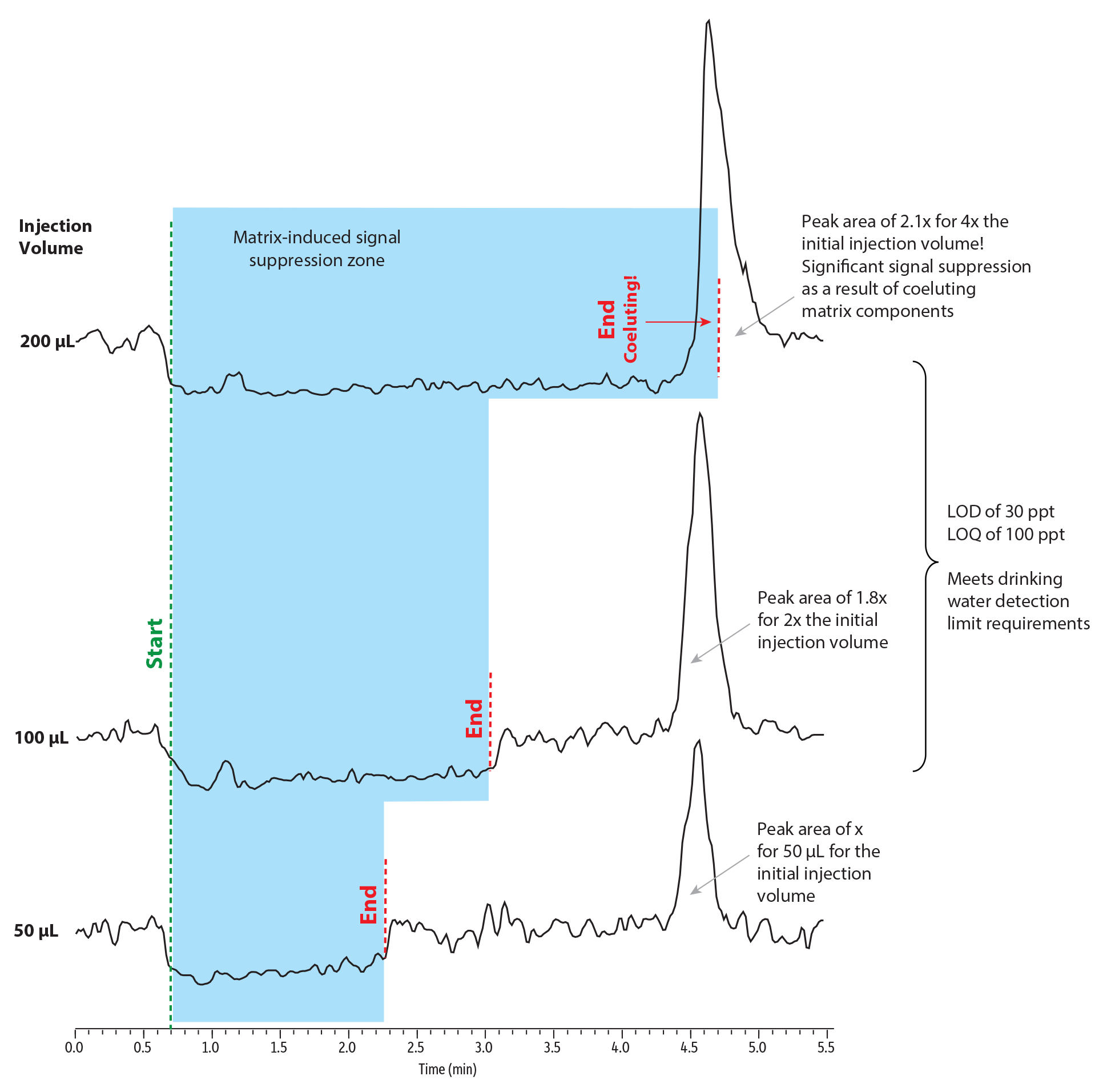

Matrix components can reduce sensitivity and accuracy, particularly at low concentrations, and their effects can be exacerbated with very high injection volumes. To demonstrate this, the LC-MS/MS analysis of acrylamide in drinking water shown in Figure 1 compares the influence of matrix across three different injection volumes. Specific effects can vary by sample, but, here, we observed a region of ionization suppression that increased in duration with larger and larger injection volumes. While early-eluting matrix components are usually diverted to waste to avoid MS contamination, we show them here to illustrate this effect and also to underscore the importance of sufficient analyte retention. At a small enough injection volume (50 µL, in this case), the zone of matrix suppression ended well before acrylamide eluted, but the volume was too small to meet sensitivity requirements. Increasing the injection volume to 100 µL increased the acrylamide signal, meeting sensitivity requirements while maintaining good peak shape. However, there are limits to how much sample can be injected and still produce good chromatographic results. For example, when we injected 200 µL, the zone of suppression was notably longer and began to encroach upon the acrylamide signal, resulting in less signal increase than would be expected for doubling the injection volume. While a column big enough to accommodate a 200 µL injection would exhibit problems related to flow rate (discussed earlier) and matrix effects, 100 µL injections on a 150 x 3.0 mm Allure Acrylamide column avoid matrix influences and allow sensitivity requirements to be met.

Figure 1: Injection volume must be high enough to meet sensitivity requirements, but not so large that the zone of matrix suppression extends into the acrylamide peak area and decreases the signal.

| Peaks | Conc. (ng/L) | Precursor | Product | |

|---|---|---|---|---|

| 1. | Acrylamide | 100 | 72.1 | 55.1 |

| Column | Allure Acrylamide (cat.# 916756E) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Dimensions: | 150 mm x 3 mm ID | |||||||||

| Particle Size: | 5 µm | |||||||||

| Pore Size: | 60 Å | |||||||||

| Guard Column: | Allure Acrylamide guard cartridge 10 mm, 2.1 mm ID, 5 µm (cat.# 916750212) | |||||||||

| Temp.: | 22 °C | |||||||||

| Standard/Sample | Acrylamide (cat.# 30494) | |||||||||

| Diluent: | Tap water | |||||||||

| Conc.: | 100 ng/L | |||||||||

| Inj. Vol.: | variable µL | |||||||||

| Mobile Phase | ||||||||||

| A: | 0.001% Formic acid in water | |||||||||

|

| Detector | MS/MS |

|---|---|

| Ion Mode: | ESI+ |

| Mode: | MRM |

| Instrument | HPLC |

| Sample Preparation | Tap water fortified with an acrylamide standard to a final concentration of 100 ng/L (ppt), which was then directly injected at 50, 100, and 200 µL injection volumes. |

| Notes | Note the encroaching suppression zone resulting from ions present in the tap water. In 50 and 100 µL injection volumes, acrylamide is well separated from this matrix effect. At 200 µL injection volume, the matrix interference affects the acrylamide peak shape and signal. |

Method Performance

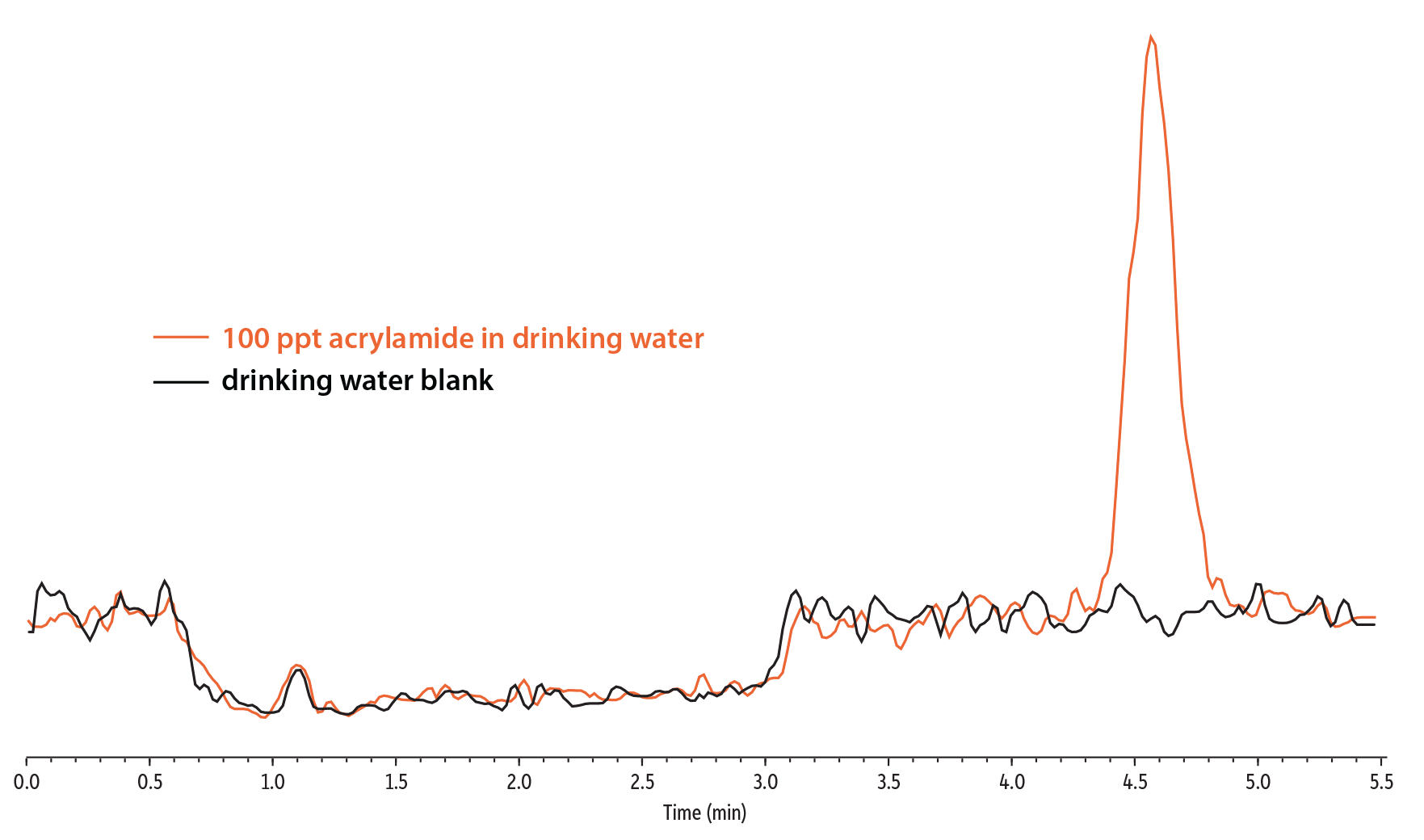

In our investigations, 100 µL injections on a 150 x 3.0 mm Allure Acrylamide column under the conditions given in Figure 2 proved to be the optimal choice for the analysis of acrylamide in drinking water by direct, large volume injection. This procedure balanced the simultaneous needs for capacity, sensitivity, and analysis time quite well. On a moderately sensitive LC-MS/MS instrument, we were able to obtain a calibration range of 30–1000 ppt, easily meeting a 100 ppt limit of quantitation (LOQ) as well as a 30 ppt limit of detection (LOD) (Figures 2 and 3).

Figure 2: Excellent response at a 100 ppt LOQ can be obtained using this large volume injection (100 µL) procedure for the analysis of acrylamide in drinking water.

| Peaks | tR (min) | Conc. (ng/L) | Precursor | Product | |

|---|---|---|---|---|---|

| 1. | Acrylamide | 4.586 | 100 | 72.1 | 55.1 |

| Column | Allure Acrylamide (cat.# 916756E) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Dimensions: | 150 mm x 3 mm ID | |||||||||

| Particle Size: | 5 µm | |||||||||

| Pore Size: | 60 Å | |||||||||

| Guard Column: | Allure Acrylamide guard cartridge 10 mm, 2.1 mm ID, 5 µm (cat.# 916750212) | |||||||||

| Temp.: | 22 °C | |||||||||

| Standard/Sample | Acrylamide (cat.# 30494) | |||||||||

| Diluent: | Tap water | |||||||||

| Conc.: | 100 ng/L | |||||||||

| Inj. Vol.: | 100 µL | |||||||||

| Mobile Phase | ||||||||||

| A: | 0.001% Formic acid in water | |||||||||

|

| Detector | MS/MS |

|---|---|

| Ion Mode: | ESI+ |

| Mode: | MRM |

| Instrument | HPLC |

| Sample Preparation | Tap water samples (1) fortified with 100 ppt acrylamide and (2) neat. |

| Notes | Direct injection with 100 µL injection volume. |

Figure 3: Calibration curve (30–1000 ppt) for acrylamide in drinking water (inset: 30 ppt LOD sample).

In conclusion, as demand grows for direct, trace-level analysis of acrylamide in drinking water, large volume injection can offer a fast, cost-effective way to meet sensitivity requirements compared to preconcentration SPE. However, large volume injection requires a number of factors to be in balance in order to be a viable option. As shown here, using 100 µL injections on a 150 x 3.0 mm Allure Acrylamide column is an effective way to employ this approach.