Excellent Separation of Neopentane and C4 Hydrocarbons

Featured Application: Neopentane Analysis on Rt-Alumina BOND/MAPD Column

- Highly selective stationary phase ideally suited for the analysis of C1-C5 hydrocarbons.

- Accurately resolves all compounds in a fast, 24-minute run time.

- Achieve a faster, 21-minute run time with good separation when using hydrogen carrier gas.

Neopentane, or 2,2-dimethyl propane (C5H12), is an impurity in C4 hydrocarbons streams, such as 1,3-butadiene, n-butane, and butylene. It is used in a variety of applications from the production of adhesives, paints, and inks to the blowing agent in the production of polystyrene foam. While neopentane analysis is performed more frequently than in the past, chemists often have difficulty separating neopentane from other hydrocarbons due to column limitations.

The unique stationary phase of Rt-Alumina BOND/MAPD columns is highly selective for C1-C5 hydrocarbons, offering excellent separation of neopentane and other impurities. Their high capacity and loadability provide exceptionally symmetrical peaks, making these columns ideal for impurity analyses at ppm concentrations. Rt-Alumina BOND/MAPD columns are manufactured using an innovative bonding process that reduces particle generation and release, resulting in robust and reproducible retention and flow.

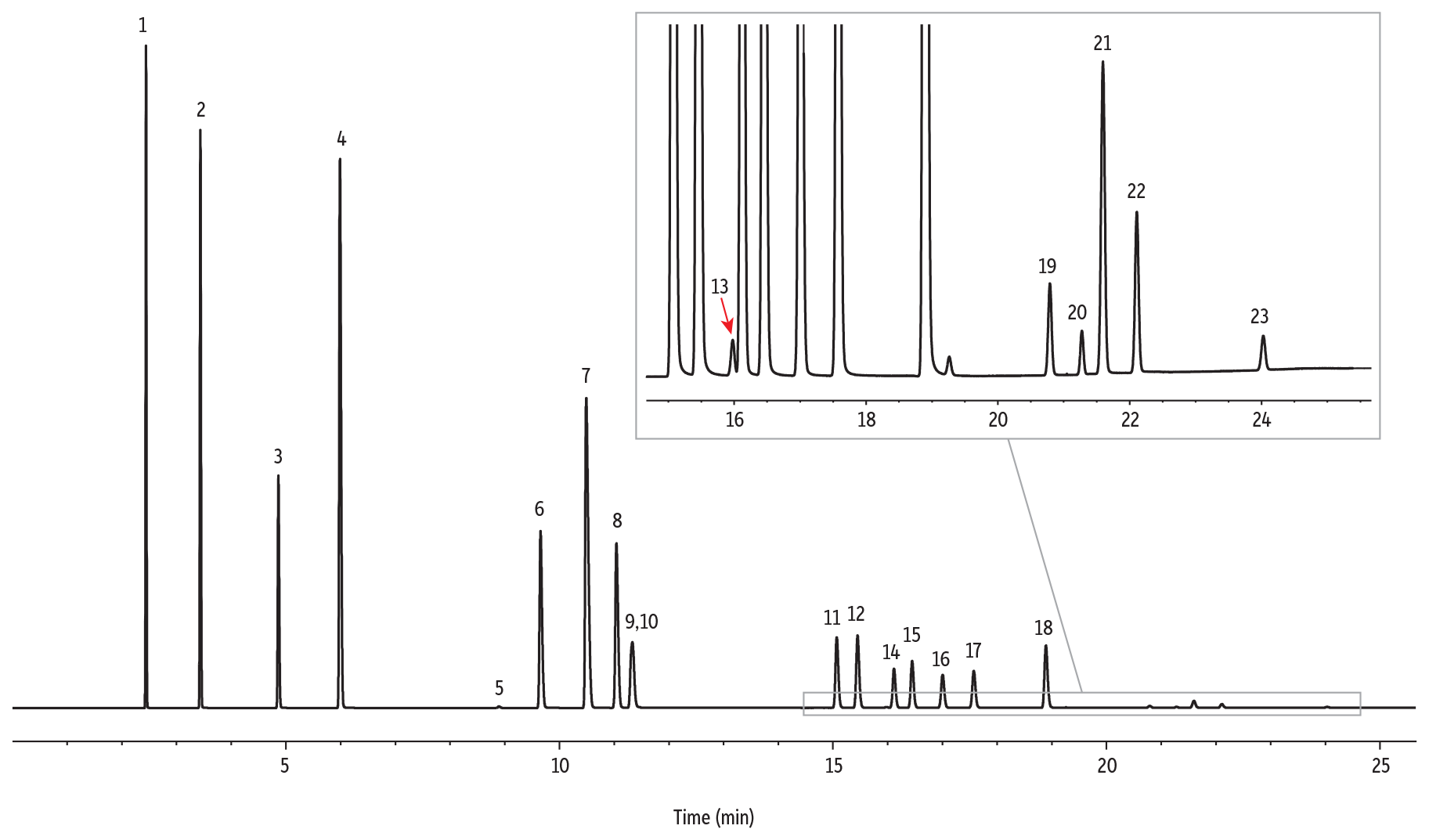

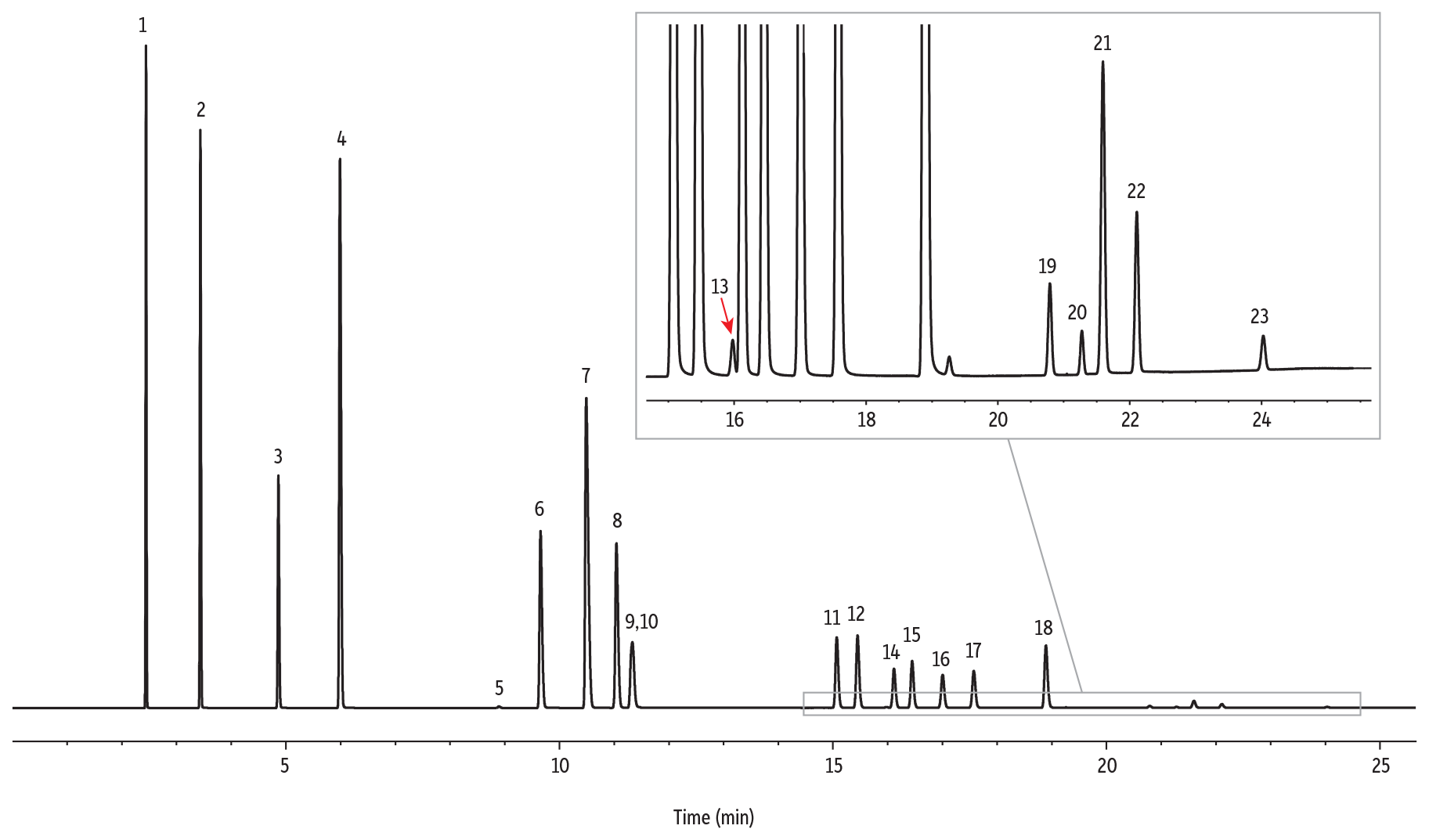

Separation of Neopentane from Other C4 Hydrocarbons on the Rt-Alumina/MAPD

GC_PC1384

GC_PC1384

| Rt-Alumina/MAPD, 50 m, 0.53 mm ID, 10 µm (cat.# 19778) |

| Helium |

| 250 μL injected via gastight syringe (cat.# 24572) |

| 250 µL split (split ratio 10:1) |

| 4.0 mm ID Topaz Precision liner w/ wool (cat.# 23305) |

| 280 °C |

| 61.92 mL/min |

| 2 min |

| 20 mL/min |

| 30 °C (hold 1 min) to 80 °C at 30 °C/min (hold 2 min) to 170 °C at 6 °C/min (hold 5 min) |

| 6.19 mL/min |

| 2.04 min @ 30 °C |

| FID @ 280 °C |

| 45 mL/min |

| N2 |

| 40 mL/min |

| 400 mL/min |

| 50 Hz |

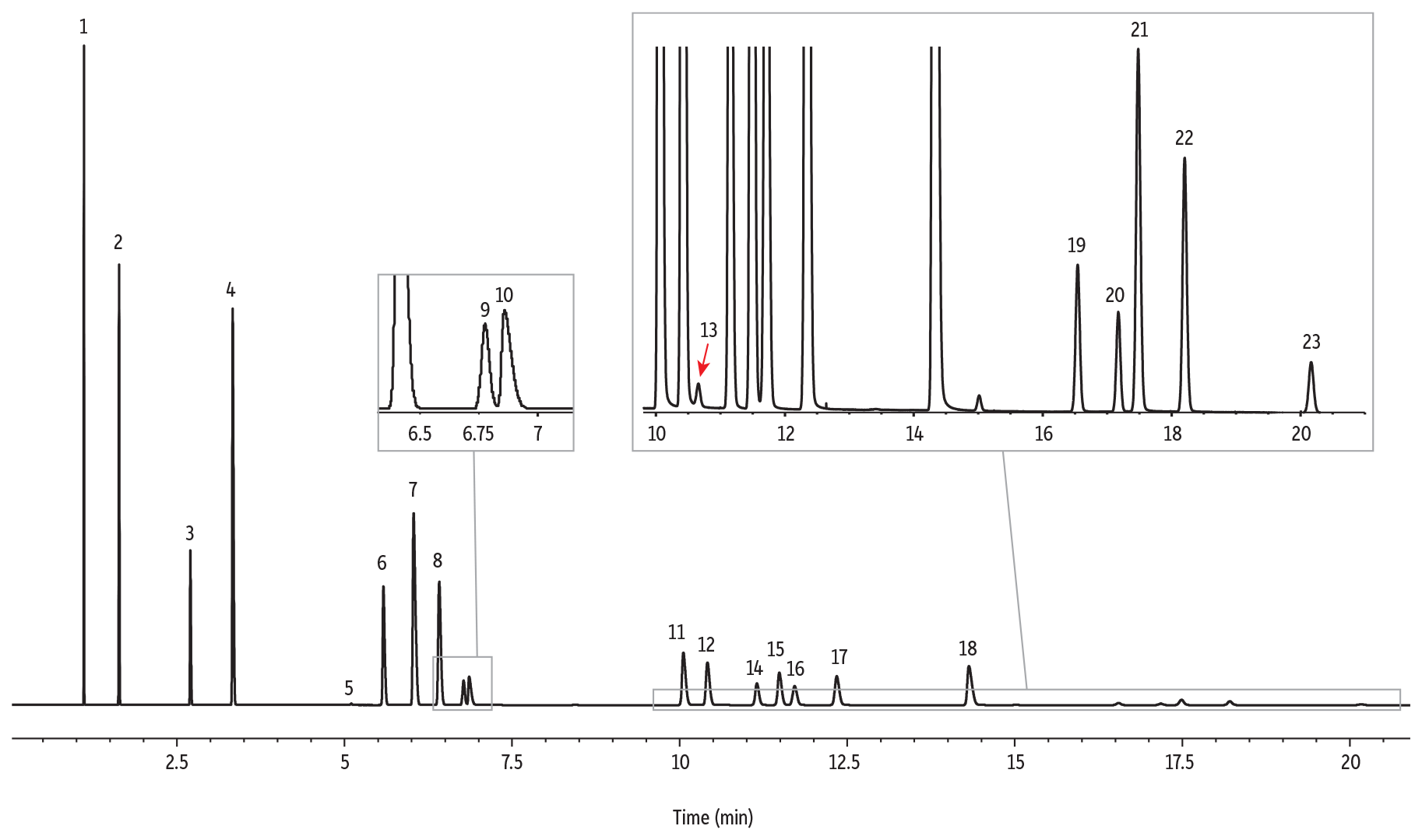

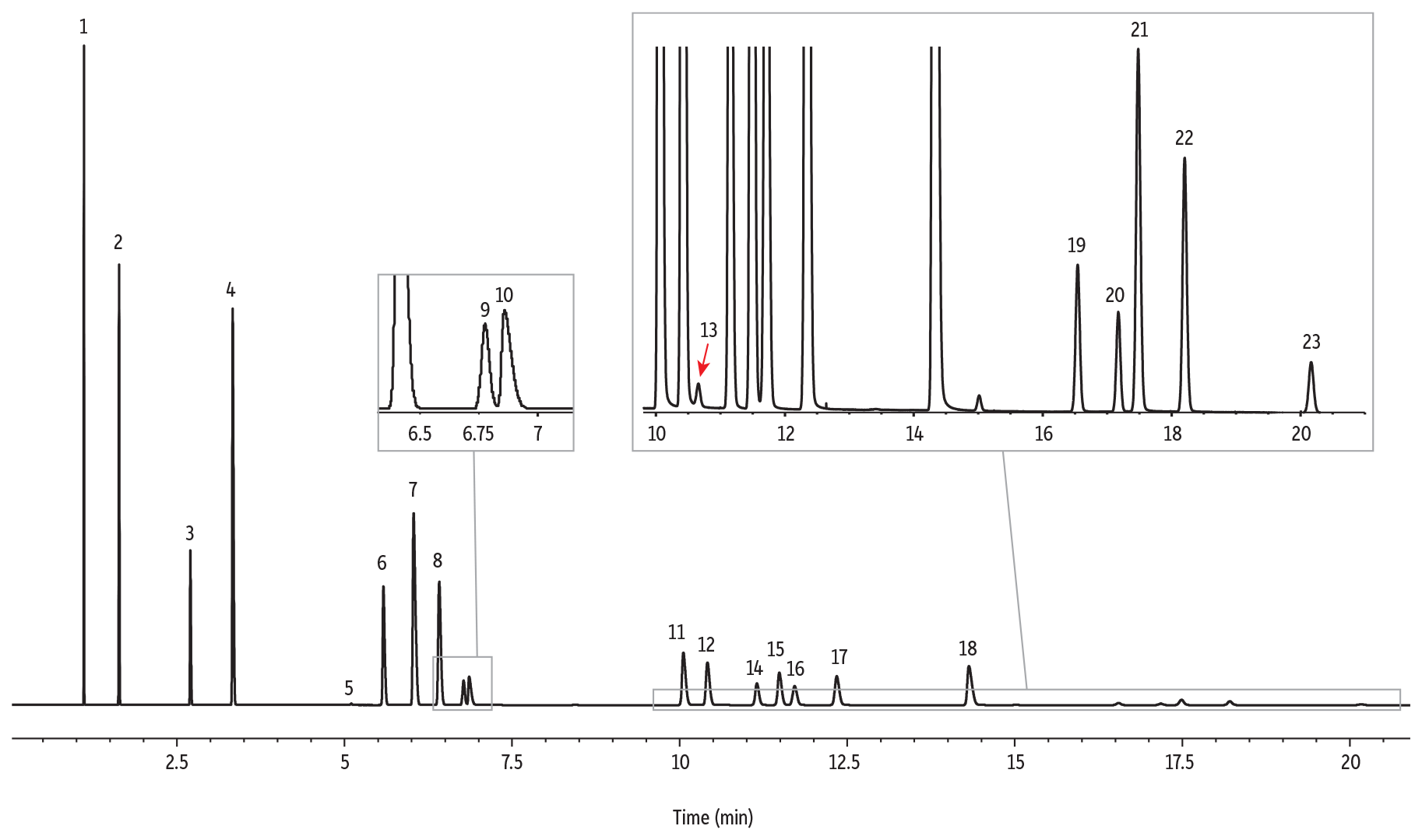

Analysis of Hydrocarbons While Maintaining Separation of Neopentane Using Hydrogen Carrier Gas on the Rt-Alumina/MAPD

GC_PC1385

GC_PC1385

| Rt-Alumina/MAPD, 50 m, 0.53 mm ID, 10 µm (cat.# 19778) |

| Helium |

| 250 μL injected via gastight syringe (cat.# 24572) |

| 250 µL split (split ratio 10:1) |

| 4.0 mm ID Topaz Precision liner w/ wool (cat.# 23305) |

| 280 °C |

| 138.12 mL/min |

| 2 min |

| 20 mL/min |

| 30 °C (hold 1 min) to 80 °C at 30 °C/min to 170 °C at 4 °C/min (hold 1 min) |

| 13.70 mL/min |

| 0.92 min @ 30 °C |

| FID @ 280 °C |

| 45 mL/min |

| N2 |

| 40 mL/min |

| 400 mL/min |

| 50 Hz |

PCFA4183A-UNV