Get Better Separation of Benzene and Ethanol with a New Two-Column Set for D3606

13 Jul 2021ASTM method D3606-20 is an EPA mandated method under the jurisdiction of ASTM international to quantify both benzene and toluene in finished motor and aviation spark ignition fuel by gas chromatography. Fuel is not permitted to exit the refinery for distribution without adhering to the method.

This test method has two procedures referenced as procedure A & B. Procedure A utilizes two capillary open tubular gas chromatographic columns and Procedure B uses two packed chromatographic columns. This blog will address procedure ‘B’, the robust packed column method for both fuel containing ethanol and also the analysis of butanol blend fuel. The performance and robustness of the column set that requires no flow changes when analyzing both gasoline containing the oxygenate ethanol and butanol blend fuel is demonstrated.

Benzene, naturally present in crude oil and as antiknock additives were reduced and subsequently eliminated from fuel, additional aromatics ie benzene and toluene were added to the gasoline for antiknock purposes. Historically benzene was added at various concentrations in gasoline and aviation spark ignition fuel to increase the octane level. Benzene is a known toxic air pollutant and is regulated by both the EPA and European Union. While the ASTM has approved both capillary and packed column methods this blog will focus solely on the more robust packed column procedure B approach.

With the addition of ethanol to gasoline circa 1978 at concentrations up to 10% modifications to the method were required to prevent the resolution factor of ethanol/benzene from falling below 1.5. The robust Restek column set easily allows the quantitation of benzene at the ASTM concentration range of 0.1% to 5% by volume. Toluene, which elutes clear of any interferences and is easily quantified in the range of 2% and 20% by volume per the ASTM method.

The benefits of this newly re-designed column set for the analysis of finished motor and aviation spark ignition fuel by gas chromatography are as follows:

- Accurate quantitation of both Benzene and Toluene

- Ethanol /Benzene >1.5 resolution

- Sec butanol / Benzene >1.5 resolution

- Two column set, no third column to install

- Column set is fully conditioned and ready use right out of the box

- Analysis of Butanol Blend fuel doesn’t require multiple flow changes as in procedure ‘A’

- Each column is tested (gasoline with ethanol) to assure method applicability

- Actual column set test chromatogram is included with each column set

- N2 is also an option for carrier gas use, however, no precision statement has yet to be developed by ASTM

- The algorithm is also included for rapid determination of the back flush time for both fuels

- All impurities in the butanol blend are resolved

- Maximum column temperature is 140 °C

Of paramount significance if the column set is housed in an auxiliary oven, manually check the oven temperature using an independent pyrometer probe to be assured it is actually at the method temperature of 135 °C. Incorrect auxiliary oven temperature and/or flow rate can also be suspected if the retention time for toluene does not match the test chromatogram supplied with each column set.

Lastly, but certainly not the least, regardless of what GC system you’re using always have oxygen and moisture getters installed on the carrier gas line as close to the GC as possible to assure trouble free column longevity.

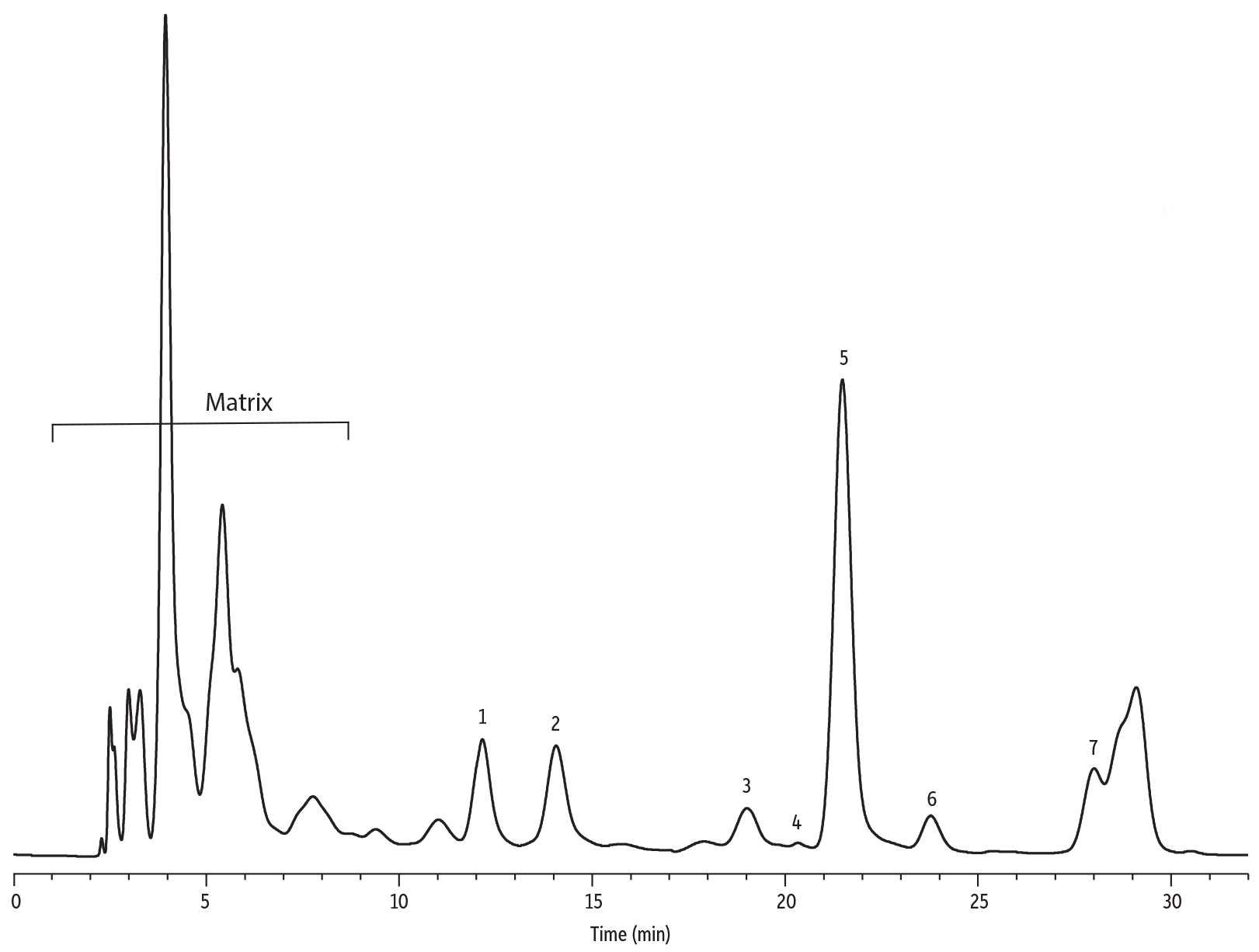

Spark Ignition Fuel with Butanol Impurities on D3606 Application Column Set by ASTM D3606-20

| Peaks | |

|---|---|

| 1. | MEK (IS) |

| 2. | Benzene |

| 3. | 2-Butanol (impurity) |

| 4. | 1-Propanol (impurity) |

| 5. | Toluene |

| 6. | Isobutanol (impurity) |

| 7. | n-Butanol |

| Column | D3606 application column (2 column set). Column 1: Sulfinert tubing, 6 ft (1.8 m), 2.00 mm ID, 0.125 in OD; Rt-D3606-1 proprietary packing material. Column 2: Sulfinert tubing, 15.5 ft (4.7 m), 2.00 mm ID, 0.125 in OD; Rt-D3606-2 proprietary packing material (cat.# 83606A-800) |

|---|---|

| Standard/Sample | Gasoline spiked with butanol impurities and MEK internal standard (IS) |

| Conc.: | Neat |

| Injection | |

| Inj. Vol.: | 0.8 µL packed not on-column |

| Liner: | Topaz 2.0 mm ID straight inlet liner (cat.# 23313) |

| Inj. Temp.: | 200 °C |

| Oven | |

| Oven Temp.: | 75 °C (hold 3 min) to 85 °C at 5 °C/min (hold 6 min) to 135 °C at 20 °C/min (hold 14 min) |

| Carrier Gas | He, constant flow |

| Flow Rate: | 25 mL/min @ 135 °C |

| Detector | FID @ 250 °C |

|---|---|

| Constant Column + Constant Make-up: | 25 mL/min |

| Hydrogen flow: | 40 mL/min |

| Air flow: | 380 mL/min |

| Instrument | Agilent/HP6890 GC |

| Notes | Valve box temperature: 150 °C Backflush (valve) times for this column set are: • Valve on at ~12.0 minutes • Valve off at 17.0 minutes Note that backflush times must be determined for each GC system. To determine the backflush time, analyze ASTM backflush standard (cat. # 30671) following the procedure described in the instruction sheet for the D3606 column set. Then, multiply the result by the algorithm 1.84. |

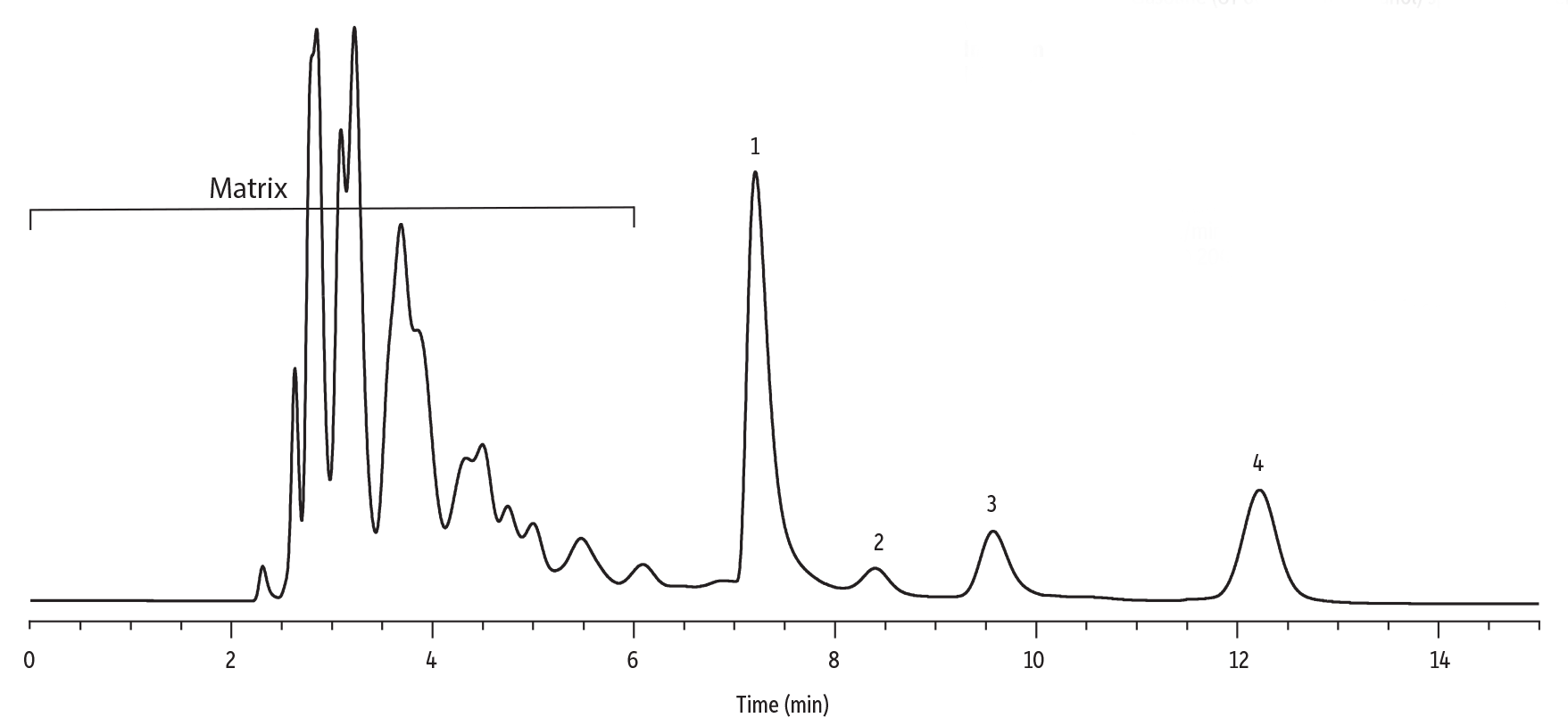

Spark Ignition Fuel Containing Ethanol on D3606 Application Column Set by ASTM D3606-20

| Peaks | tR (min) | Conc. | |

|---|---|---|---|

| 1. | Ethanol | 7.21 | <10% |

| 2. | Benzene | 8.40 | <5% |

| 3. | 2-Butanol (IS) | 9.57 | 4% |

| 4. | Toluene | 12.22 | <20% |

| Column | D3606 application column (2 column set). Column 1: Sulfinert tubing, 6 ft (1.8 m), 2.00 mm ID, 0.125 in OD; Rt-D3606-1 proprietary packing material. Column 2: Sulfinert tubing, 15.5 ft (4.7 m), 2.00 mm ID, 0.125 in OD; Rt-D3606-2 proprietary packing material (cat.# 83606A-800) |

|---|---|

| Standard/Sample | Gasoline (87 octane with ethanol) spiked with internal standard (IS) |

| Conc.: | Neat |

| Injection | |

| Inj. Vol.: | 1.5 µL packed not on-column |

| Liner: | Topaz 2.0 mm ID straight inlet liner (cat.# 23313) |

| Inj. Temp.: | 200 °C |

| Oven | |

| Oven Temp.: | 135 °C (hold 15 min) |

| Carrier Gas | He, constant flow |

| Flow Rate: | 25 mL/min @ 135 °C |

| Detector | TCD @ 200 °C |

|---|---|

| Instrument | Agilent/HP6890 GC |

| Notes | Valve box temperature: 150 °C Backflush (valve) times for this column set are: • Valve on at ~4.3.0 minutes • Valve off at 12.0 minutes Note that backflush times must be determined for each GC system. To determine the backflush time, analyze ASTM backflush standard (cat. # 30671) following the procedure described in the instruction sheet for the D3606 column set. Then, multiply the result by the algorithm 2.33. |